- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Double Slider Crank Mechanism: Definition and Inversions

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Let’s first discuss the mechanism before discussing the Double Slider Crank Mechanism. A mechanism is a device that turns the required input and motion set into the necessary output forces and motion. Moving parts in mechanisms include gears and gear trains, belts and chain drives, cams and followers, linkages, and so on. Machine elements include friction devices such as brakes and clutches and structural components. Typically, a mechanism is part of a larger process known as a mechanical system or machine. A mechanism can also refer to a whole machine, such as a vehicle’s steering mechanism or a watch’s winding mechanism. A machine, on the other hand, is commonly defined as a collection of many mechanisms.

Double Slider Crank Mechanism PDF

Two sliding pairs and two twist pairs make up the double slider crankshaft. The double slider crankshaft is so named because it has two sliding pairs. It consists of two sliders, a moving frame, and a link that links the two slides and fixes the distance between the two sliders. Let’s deeply dive into the concepts related to Double Slider Crank Mechanism.

Download Formulas for GATE Mechanical Engineering – TOM & Vibrations

Table of content

Double Slider Crank Mechanism

The twin slider-crank linkage comprises four links connected by a kinematic chain that includes two revolute joints and two sliding or prismatic joints. One sliding limitation in this twin slider is perpendicular to the other. The double slider crank mechanism is essential for the GATE exam. These devices can convert the crank’s circular motion into an accurate sinusoidal motion of the link traveling within the specified linear constraint.

Inversion of Double Slider Crank Mechanism

A mechanism fixes one of the links of a kinematic chain. Different mechanisms can be generated by affixing links to the same kinematic chain. These are known as mechanism inversions. Mechanism inversions are majorly questioned in the GATE question papers. The number of mechanisms that can be obtained by modifying the fixed link equals the number of links. Except for the initial mechanism, all other mechanisms will be referred to as inversions of the original mechanism. The motion of a mechanism’s relative connections is unaffected by inversion.

Two sliding pairs and two twist pairs make up the double slider crankshaft. Because it contains two sliding pairs, it is called a double slider crankshaft. It consists of two sliders, a moving frame, and a link that links the two slides and fixes the distance between the two sliders. Similar to the inversions of the single slider crank mechanism, inversions of this mechanism exist. The slider frame comprises two straight grooves forming a single link and cutting each other at right angles. The double slider crank chain has three major inversions as follows:

- Elliptical Trammels

- Scotch Yoke Mechanism

- Oldham’s Coupling

Download Formulas for GATE Mechanical Engineering – Manufacturing Engineering and Materials

Elliptical Trammels

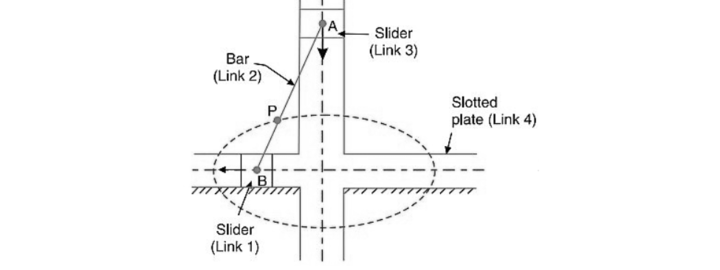

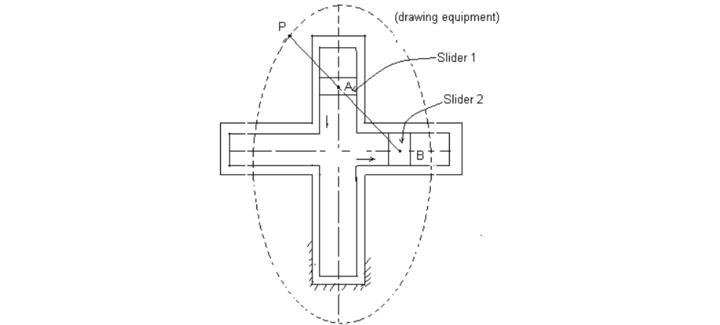

The ellipse is drawn using this form of the inverse. It is also known as Archimedes’ trend. This inversion mechanism can be used to create ellipses of various diameters. The frame is fixed in this inverted link 1. This frame’s grooves are used by both sliders, links 2 and 4. The first slider moves vertically, while the second moves horizontally. The motion of the sliding bars is restricted by the connecting rod link 3, which links the two sliding bars, link 2 and link 4. Each point on the connecting rod represents the location of an ellipse as the two sliders move. The connecting rod’s various points will generate a separate ellipse.

Scotch Yoke Mechanism

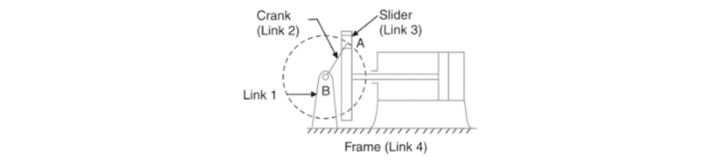

Scotch Yoke mechanisms transform rotary motion into reciprocating motion. Fixing either link 1 or link 3 results in the inversion. When link 2 (which corresponds to the crank) spins around B as the centre, link 4 (which corresponds to the frame) reciprocates. The frame is guided by fixed link 1. If the second slider’s path is tracked, it will spin around the fixed slider and make a circle. If the frame or slanted plate moves forward and the horizontal moving slider is fixed while the frame moves up and down, the vertical moving slider is fixed.

Download Formulas for GATE Mechanical Engineering – Strength of Materials

Oldham’s Coupling

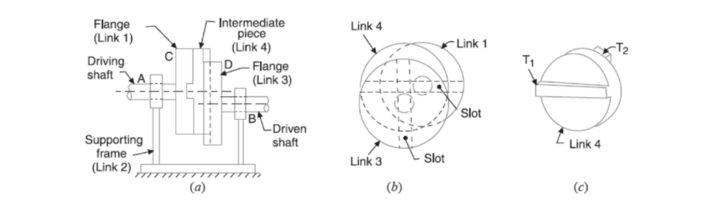

Oldham couplings join two shafts with distinct axles and rotate them at the same speed. An Oldham coupling mechanism joins two parallel shafts with short axel separations. The shafts are linked so that when one shaft rotates, the other shaft rotates at the same rate. Fixing link 2 achieves this inverse. The shaft to be linked has two flanges (links 1 and 3), which are forged to their ends. It forms the inverted Oldham coupling. Now we’ll look at how it can join two shafts with somewhat differing axes.

The two flanges are attached to the ends of the two shafts that will be joined. Forging is used to rigidly fasten these flanges at the end. There are grooves on both flanges. Both flanges’ grooves are perpendicular to one another. A center flange is put between these two flanges and fits into the grooves of both flanges. Oldham coupling is an important part of the GATE ME syllabus. This coupling has fixed frame links 3, a driving shaft and a driving flange for link 2, an intermediate flange for link 1, and a driveshaft and a flange for link 4. When the first shaft, the driving shaft, turns, the forged shaft rotates, and the center flange in the grooves of the driving flange begins to rotate. The driven flange then begins to revolve since the center flange is also fixed in the grooves of the driven flange, and as the driven flange rotates, so does the driven shaft.

Get complete information about the GATE exam pattern, cut-off, and all those related things on the Byju Exam Prep official youtube channel.