- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Connecting Rod

By BYJU'S Exam Prep

Updated on: September 25th, 2023

A connecting rod is a component of a piston engine that connects the piston to the crankshaft. It is typically made of steel or aluminum and has a specific length and shape that allows it to transfer the motion of the piston to the crankshaft. In a four-stroke engine, the connecting rod is responsible for converting the reciprocating motion of the piston into the rotational motion of the crankshaft.

Connecting Rod PDF [GATE Notes]

The connecting rod plays a crucial role in the functioning of a piston engine. It must be strong enough to withstand the forces exerted on it by the piston but also light enough to avoid adding too much weight to the engine. It must also be carefully balanced to ensure smooth operation and avoid excess wear on the engine’s other components. Additionally, the connecting rod must be properly aligned with the crankshaft and piston to ensure efficient motion transfer.

Table of content

What is a Connecting Rod?

A connecting rod is a mechanical part that connects the piston to the crankshaft in a reciprocating engine. It is responsible for transmitting the force from the piston to the crankshaft and converting the reciprocating motion of the piston into the rotary motion of the crankshaft. This allows the engine to power machinery and vehicles.

Formulas for GATE Mechanical Engineering – Strength of Materials

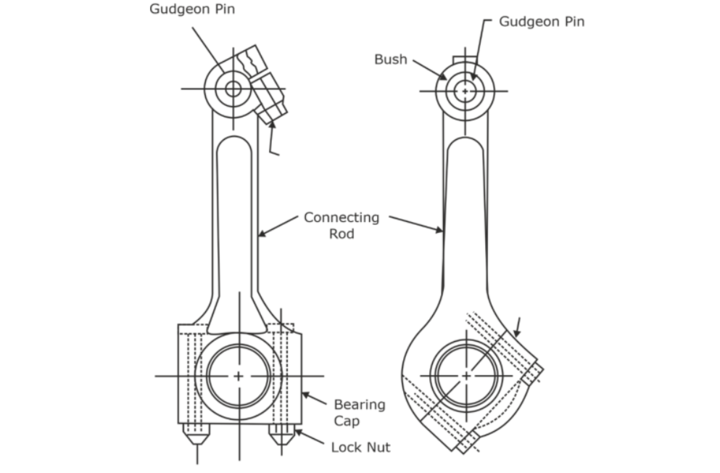

Connecting Rod Diagram

A connecting rod diagram is a visual representation of a connecting rod, which is a critical component in an engine. The diagram typically shows the connecting rod in relation to other parts of the engine, such as the piston, crankshaft, and cylinder. It may also include labels and other annotations to help explain the function and operation of the connecting rod. The diagram is often used to study and understand an engine’s design and operation.

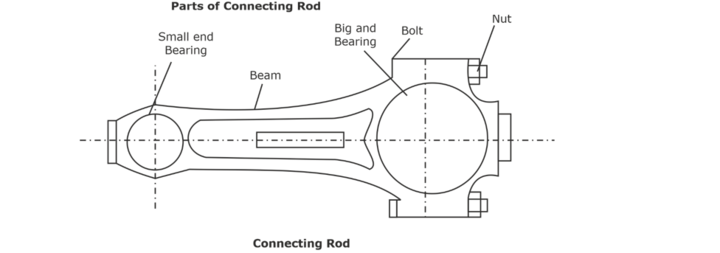

Parts of Connecting Rod

A connecting rod is a mechanical component that connects together two other mechanical parts, such as a piston and a crankshaft. It typically consists of several different parts, including the following:

-

Rod body: This is the main part of the connecting rod and is typically made from strong, durable steel. It has a cylindrical shape with rounded ends and is designed to withstand the stresses and forces applied to it during operation.

-

The big end and small end: The big end is the larger, rounded end of the connecting rod, which is attached to the crankshaft. The small end is the smaller, rounded end, which is attached to the piston. The rod body connects the big and small ends, designed to pivot and rotate relative to each other.

-

Crank pin: The crank pin is a cylindrical component attached to the crankshaft and extends into the big end of the connecting rod. The crank pin allows the connecting rod to pivot and rotate relative to the crankshaft as the piston moves up and down in the cylinder.

-

Gudgeon pin: The gudgeon pin, also known as a wrist pin or piston pin, is a small cylindrical component attached to the piston and extends into the small end of the connecting rod. The gudgeon pin allows the connecting rod to pivot and rotate relative to the piston as the crankshaft rotates.

-

Bearings: Connecting rods typically have bearings at both the big and small ends, allowing them to pivot and rotate smoothly. These bearings may be made from various materials, such as bronze or a low-friction synthetic polymer.

-

Bolts and nuts: Connecting rods are often held together with bolts and nuts, which allow them to be easily disassembled and reassembled for maintenance or repair. These bolts and nuts may be made from various materials, such as steel or an alloy.

Formulas for GATE Mechanical Engineering – Machine Design

Types of Connecting Rod

Several different types of connecting rods are used in different applications, depending on the specific requirements of the system in which they are used. Some common types of connecting rods include the following:

-

H-beam connecting rods: H-beam connecting rods are the most common connecting rod used in many internal combustion engines. They are named for their distinctive H-shaped cross-section, which provides a strong and rigid structure that can withstand the high stresses and forces applied to the rod during operation.

-

I-beam connecting rods: I-beam connecting rods are similar to H-beam connecting rods but have an I-shaped cross-section instead of an H-shaped cross-section. This provides a slightly different balance of strength and weight, and I-beam connecting rods are often used in high-performance engines that require a lightweight and strong connecting rod.

-

Forged steel connecting rods: Forged steel connecting rods are made from a single piece of steel that is heated and shaped under pressure to create the finished connecting rod. This process creates a strong and durable connecting rod well-suited for high-stress applications.

-

Aluminum connecting rods: Aluminum connecting rods are made from aluminum, a lightweight and strong material. They are often used in engines that require a lightweight connecting rod, such as racing or small engines.

-

Titanium connecting rods: Titanium connecting rods are made from titanium, a strong, lightweight, and corrosion-resistant material. They are often used in high-performance engines requiring a lightweight, strong connecting rod.

-

Powder-metal connecting rods: Powder-metal connecting rods are made from a mixture of metal powders that are compressed and heated to create the finished connecting rod. This process allows for creation of complex shapes and designs, and powder-metal connecting rods are often used in high-performance engines.

- Piston Connecting rods: A piston connecting rod is a rod that connects the piston to the crankshaft in an engine. It is a critical component in the engine’s operation, as it transfers the motion of the piston to the crankshaft, allowing the engine to generate power. The connecting rod must be strong enough to support the piston’s weight and withstand the piston’s forces as it moves up and down in the cylinder. It must also be able to move freely within the cylinder so that the piston can travel without obstruction. The material used for the connecting rod and its design and dimensions is important factors in the performance and efficiency of the engine.

- Bearing Connecting Rods: A bearing connecting rod is a connecting rod that has bearings installed on its ends. The bearings allow the connecting rod to rotate smoothly around the crankshaft and piston, reducing friction and improving the engine’s efficiency. Two main bearings are used in connecting rods: plain bearings and journal bearings. Plain bearings are simple, low-cost bearings with a metal surface coated with a material, such as copper or lead, to reduce friction. On the other hand, journal bearings are more complex and typically made of a metal alloy. They use a lubricating oil film to reduce friction and support the weight of the connecting rod and piston. The choice of bearing type for a connecting rod will depend on the engine’s specific requirements and the design team’s priorities.

Applications of Connecting Rod

Connecting rods are a key component in many mechanical systems and are used in many applications. Some common examples include:

- Internal combustion engines: In engines that use a piston and connecting rod assembly, the connecting rod connects the piston to the crankshaft. As the piston moves up and down in the cylinder, the connecting rod transmits the motion of the piston to the crankshaft, which converts the linear motion of the piston into rotational motion.

- Hydraulic systems: Connecting rods are commonly used in hydraulic systems to transmit the linear motion of a hydraulic piston to a mechanical component, such as a crank or lever.

- Robotics: In many robotic systems, connecting rods link different mechanical components and transmit motion from one part of the robot to another.

- Mechanical clockwork: In mechanical clocks and other clockwork systems, connecting rods are often used to transmit motion from the escapement mechanism to the hands of the clock.

- Musical instruments: Connecting rods are sometimes used in musical instruments, such as pianos and harpsichords, to transmit the motion of a key or pedal to a mechanical component that produces sound.

Connecting Rod Material

The material used for engine connecting rods can vary depending on the intended application and the engine’s design. Common materials for connecting rods include steel, aluminum, and titanium. Each of these materials has unique properties that make it suitable for a connecting rod. For example, steel is known for its strength and durability, while aluminum is lightweight and has good thermal conductivity. On the other hand, Titanium is very strong and lightweight but also very expensive. Ultimately, the material for a connecting rod will depend on the engine’s specific requirements and the design team’s priorities.

Functions of Connecting Rod

The connecting rod is a critical component in an engine, as it connects the piston to the crankshaft and transfers the motion of the piston to the crankshaft. This motion is what drives the engine and allows it to generate power. There are several key functions of the connecting rod in an engine, including:

-

Transferring the motion of the piston to the crankshaft: The connecting rod converts the piston’s up-and-down motion into the rotational motion of the crankshaft.

-

Supporting the weight of the piston: The connecting rod must be strong enough to support the weight of the piston and any other loads placed on it, such as the pressure of the combustion gases in the cylinder.

-

Allowing the piston to move freely: The connecting rod must be able to move freely within the cylinder so that the piston can travel up and down without any obstruction.

-

Absorbing the forces generated by the piston: The connecting rod must be able to withstand the forces generated by the piston as it moves up and down, such as the pressure of the combustion gases and the impact of the piston hitting the cylinder head.

Overall, the connecting rod plays a vital role in the operation of an engine by transferring motion, supporting weight, and absorbing forces.

Importance of Connecting Rod

Connecting rods are an important component in many mechanical systems and play a crucial role in the operation of these systems. Some of the key reasons why connecting rods are important to include the following:

-

Transmitting motion: Connecting rods connect two mechanical parts, such as a piston and a crankshaft, and transmit the motion of one part to the other. This allows for efficient motion transfer between different parts of a mechanical system, which is essential for proper operation.

-

Converting motion: In many systems, connecting rods are used to convert the linear motion of a piston into the rotational motion of a crankshaft. This is essential in systems such as internal combustion engines, where the motion of the pistons must be converted into rotational motion to drive the wheels or other components of the vehicle.

-

Withstanding forces: Connecting rods are designed to withstand the high stresses and forces applied during operation. This allows them to transmit and convert motion effectively without breaking or failing under the forces applied to them.

-

Reducing friction: Connecting rods typically have bearings at both the big and small ends, allowing them to pivot and rotate smoothly. This reduces friction and wears between the connecting rod and the other mechanical components it is connected to, which helps improve the system’s efficiency and longevity.

-

Enabling design flexibility: Connecting rods come in a variety of different shapes, sizes, and materials, which allows designers to choose the best connecting rod for their specific application. This flexibility in design allows for creation of a wide range of mechanical systems optimized for different purposes and requirements.

Connecting Rod Engine

A connecting rod engine is an engine that uses a connecting rod to connect the piston to the crankshaft. This type of engine is also known as a reciprocating engine because the motion of the piston is

eciprocating – moving back and forth in a straight line. Connecting rod engines are commonly found in internal combustion engines, such as those used in cars and trucks. In these engines, the connecting rod transfers the motion of the piston, which is driven by the combustion of fuel, to the crankshaft. The crankshaft then converts this into rotational motion, which drives the vehicle’s wheels. Connecting rod engines are also used in some steam engines and other types of engines.