- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Composite Beams – Definition & Types of Composite Beams

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Composite beams are formed from two different materials as wood concrete, steel-wood, plastic-concrete, and different polymer material with concrete. To use composite beams in a structure we use an equivalent section using the concept of modular ratio termed “m”.

Sometimes for limitations of design, utility, and requirement beam sections are not utilized as either they do not fulfill the strength criteria or do not full fill the dimension, space, aesthetic, or any criteria that belong to design are not full filled. In that case, more than one material is utilized to casting the beam known as composite beams. In this article, we get to know about composite beams’ properties and their function.

Table of content

What are Composite Beams?

The composite beams are made up of different types of material. In our design time, a single material sometimes does not meet strength requirements like concrete is weak in tension, steel has high vibration, wood is weak in compression, and plastic is ductile in nature hence two different types of materials are used to form the composite beams.

Composite beams are applied to places where normal beams do not provide serviceability. As we use the composite beams of higher stiffness material cross-sectional area can be reduced to an extent. They are used to increase the strength of the structure.

Function of Composite Beams

Composite beams have the function of when the load is high and space is less, to use the composite material with high grade of materials using we can optimize the structure for its strength, durability, and serviceability.

Generally in pure steel structure beams have a corrosion resistance issue, to reduce this effect the steel structure merged with high-strength plastic or wood, this is also a function of composite beams.

Properties of Composite Beams

In general, mostly steel concrete composite beams are used nowadays. Here we get to know the properties of steel-concrete composite beams. As we know that concrete is taken a high compressive load while steel is can take a high tensile load.

The combination of these two makes steel-concrete composite beams that is can withstand high temperature or low temperature because concrete can provides rigidity and steel has the property to shrink and compact.

Composite beam neutral axis remains in steel material section by this section behaves as limit state method. The composite beam of steel, the section provides sufficient ductility that can provide the warning prior to failure of the structure.

To use in a single structure we need to know the single factor of the strength of these two materials in composite beams. That ratio is called a modular ratio and is denoted by m.

Example: Compressive strength of concrete material is like = 4 ksi (kilo pound per square inch)

Solution: Maximum yield strength of steel in tension = 36 ksi

Elastic modulus of concrete = 3644 ksi

Elastic modulus of steel 29000 ksi

Now the modular ratio = (Elastic modulus of steel) / (Elastic modulus of concrete) Hence-

m = (Elastic modulus of steel) / (Elastic modulus of concrete) = 29000/3644 = 7.96

Composite Beam Calculator

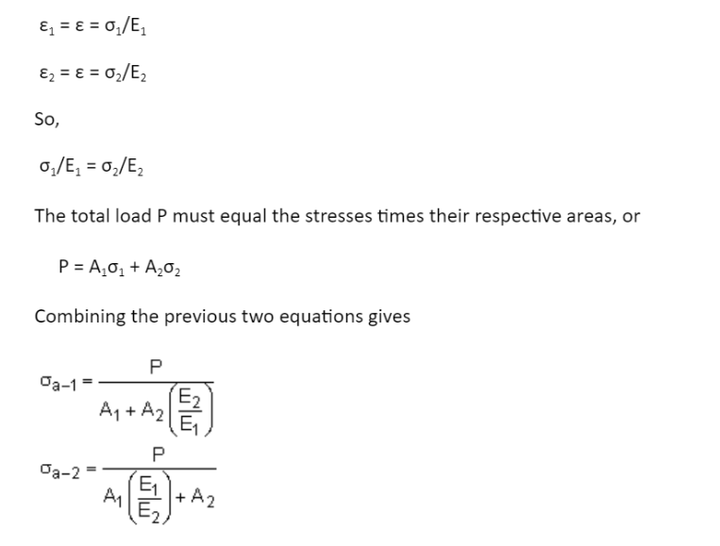

Composite beam strength or modular ratio can be calculated manually or by using of different types of software. Here we can discuss the manual method to calculate the composite beam factor. Let us take a simple beam with different material under the axial loading now,

we know –

The stress can be calculated in this way and here E1/E2 is a modular ratio of different materials used.

| Important Topics for Gate Exam | |

| Brittle Material | Capacitors in Parallel |

| Capacitors in Series | Carnot Cycle |

| Cement Test | Clamping Circuit |

| Clipping Circuit | CMOS Fabrication |

| CMOS Converter | Column Base |