- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Springs Study Notes for Mechanical Engineering

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Springs play a crucial role as mechanical components designed to store and release mechanical energy. They are used in a wide range of applications and are essential in many devices and systems to provide functionality and control. Their versatility makes them indispensable in various industries and everyday products.

In this article, we provide Springs Study Notes for Mechanical Engineering which cover its basic functions, materials used for Springs, and different types of Springs.

Download Formulas for GATE Mechanical Engineering – TOM & Vibrations

Springs:

Spring is defined as an elastic machine element, which deflects under the action of the load and returns to its original shape when the load is removed.

Basic Functions of Spring

- Cushioning, absorbing, or controlling of energy due to shock and vibration. example: Car

- Springs or railway buffers

- To control energy, springs-supports, and vibration dampers.

- Control of motion, and maintaining contact between two elements (cam and its follower)

- Creation of the necessary pressure in a friction device (a brake or a clutch)

- Restoration of a machine part to its normal position when the applied force is withdrawn (a governor or valve). A typical example is a governor for turbine speed control. A governor system uses a spring-controlled valve to regulate the flow of fluid through the turbine, thereby controlling the turbine speed.

- Measuring forces, spring balances, gages

- Storing of energy, in clocks or starters, the clock has the spiral type of spring which is wound to the coil and then the stored energy helps gradual recoil of the spring when in operation.

Materials Used for Spring: One of the important considerations in spring design is the choice of the spring material. Some of the common spring materials are given below.

- Hard-drawn wire: This is cold drawn, cheapest spring steel. Normally used for low stress and static load. The material is not suitable at subzero temperatures or at temperatures above 120°C.

- Oil-tempered wire: It is a cold drawn, quenched, tempered, and general purpose spring steel. However, it is not suitable for fatigue or sudden loads, at subzero temperatures and at temperatures above 180°C. When we go for highly stressed conditions then alloy steels are useful.

- Chrome Vanadium: This alloy spring steel is used for high stress conditions and at high temperature up to 220°C. It is good for fatigue resistance and long endurance for shock and impact loads.

- Chrome Silicon: This material can be used for highly stressed springs. It offers excellent service for long life, shock loading and for temperature up to 250°C.

- Music wire: This spring material is most widely used for small springs. It is the toughest and has highest tensile strength and can withstand repeated loading at high stresses. However, it cannot be used at subzero temperatures or at temperatures above 120°C. Normally when we talk about springs we will find that the music wire is a common choice for springs.

- Stainless steel: Widely used alloy spring materials.

- Phosphor Bronze / Spring Brass: It has good corrosion resistance and electrical conductivity. That’s the reason it is commonly used for contacts in electrical switches. Spring brass can be used at subzero temperatures.

Download Formulas for GATE Mechanical Engineering – Manufacturing Engineering and Materials

Helical spring:

Springs are classified according to their shape.

- The spring can be a helical coil of a wire, a piece of stamping or a flat wound-up strip

- The most popular type of spring is helical spring

- The helical spring is made from a wire, usually of usually of circular cross-section, which is bent in the form of a helix

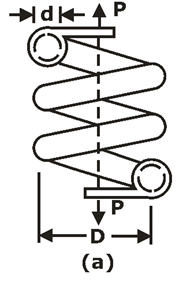

- There are two types of helical springs – compression spring and extension spring.

Fig. (a) Helical Compression spring, (b) Helical Extension spring

TERMINOLOGY OF HELICAL SPRING:

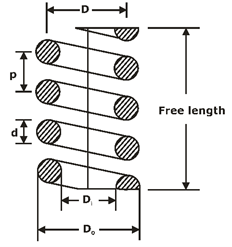

Fig.: Anatomy of helical spring

d = wire diameter of spring (mm),

Di = inside diameter of spring coil (mm),

Do=Outside diameter of spring coil (mm),

D=mean coil diameter (mm).

Formulas for GATE Mechanical Engineering – Strength of Materials

Therefore,

Spring index(C) = Ratio of mean coil diameter to wire,

SOLID LENGTH:

Axial length of the spring which is so compressed that the adjacent coils touch each other. The spring is completely compressed and no further compression is possible.

Solid Length = Nt d

where, Nt = total number of coils,

COMPRESSED LENGTH:

Axial length of the spring, which is subjected to maximum compressive force.

When the spring is subjected to maximum force, there should be some gap or clearance between the adjacent coils.

The gap is essential to prevent clashing of the coil.

Total gap = (Nt – 1) x gap between adjacent coils

FREE LENGTH:

Axial length of an unloaded helical compression spring. In this case, no external force acts on the spring.

STIFFNESS OF THE SPRING:

Force required to produce unit deflection,

where, P = axial spring force (N)

δ= axial deflection of the spring corresponding to the force (mm)

STRESS AND DEFLECTION EQUATIONS:

There are two basic equations for the design of helical springs,

load – stress equation and load-deflection equation

A helical spring made from the wire of circular cross-section is shown in figure,

Fig.: Helical spring under action of tensile force

Spring Index

- Spring index is defined as the ratio of the mean coil diameter to the wire diameter of the spring and denoted as “C”.

C = D/d = Mean coil diameter / Wire diameter

- The spring index indicates the relative sharpness of curvature of the coil.

Shear stress correction factor is defined as,

Wahl correction factor is defined as,

Resultant shear stress in the spring wire,

Axial deflection ‘ δ ’ of the spring:

Rate of spring:

SERIES AND PARALLEL CONNECTIONS OF SPRINGS:

FOR SERIES CONNECTION:

Fig.: Series connection

The total deflection of the spring combination is equal to the sum of the deflections of individual springs,

FOR PARALLEL CONNECTION:

Fig.: Parallel connection

The force acting on the spring combination is equal to the sum of forces acting on individual springs, i.e.

The deflection of individual springs is same and equal to the deflection of the combination, i.e.

Therefore,

If you are preparing for GATE and ESE, avail Online Classroom Program to get unlimited access to all the live structured courses and mock tests from the following link: