- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

What are the Different Types of Keys in Machine Design?

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Keys and various Types of Keys in Machine Design are used to join the Mechanical components. There are elements like nut and bolt, screw, keys, and couplings, joints like cotter joints, and knuckle joints that are used for non-permanent joining and non-permanent fastening of mechanical components. As we focus on the simplest elements used for joining the mechanical components, types of keys in Machine Design are one of them.

In the list of machine design elements, the Key is one of the most important elements. One of the best features of the Key joint is it is detachable, so the key can be used as a temporary fastening. In this article, we will see about the keys, the design of keys, key joints, the function of key joints, and the types of keys in Machine Design in detail.

Table of content

What are Keys in Machine Design?

Key is one of the machine element parts, used to connect transmission shaft to rotating machine elements like gear, flywheel, sprockets, or pulleys. So based on the uses and function of keys Generally, keys are made up of ductile materials like mild steel and plain carbon steel by hardening and tempering. In the case of corrosive environment brass and stainless steel material are used to design a key. For safety purposes, 3-4 factors of safety should be provided.

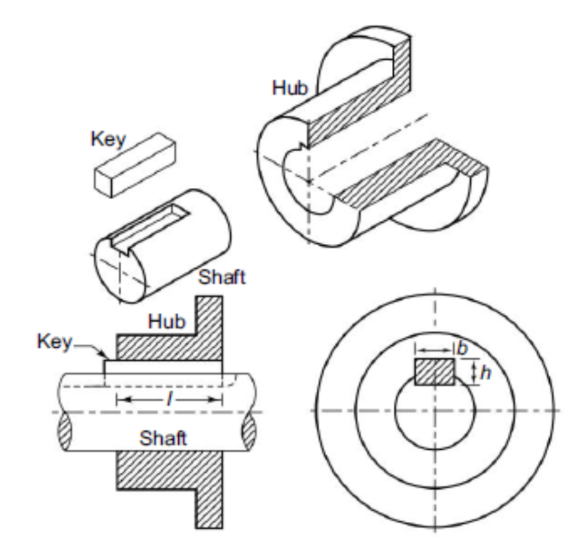

The design of the key joint consists of a shaft, hub, and key as shown below fig. The slot is provided in the rotating shaft or in the hub or both of them to insert the key known as keyways. The keyway is usually manufactured by a vertical or horizontal milling cutter. The key is inserted inside the keyway parallel to the axis of the rotation.

Types of Keys in Machine Design

Keys are simple rectangular or circular bar elements with slight changes in shape. and sometimes some integral added as per the design and requirements. Based on the design, function, requirements, and working conditions types of keys in Machine Design are as follows:

- Sunk Key

- Saddle Keys

- Flat saddle Key

- Hollow saddle key

- Tangent Keys

- Round Keys

- Spindle Key

Sunk Key

The sunk key is inserted in both the rotating shaft and the hub or boss of the mating element. Some portion of the sunk keys is inside the rotating shaft and some of the portions are inside the hub or boss. It is used in the case of the positive drive case. Based on the shape and design of the key it can be further following types:

- Rectangular sunk key

- Square sunk key

- Parallel sunk key

- Gib-head key

- Feather key

- Woodruff key

Saddle Key

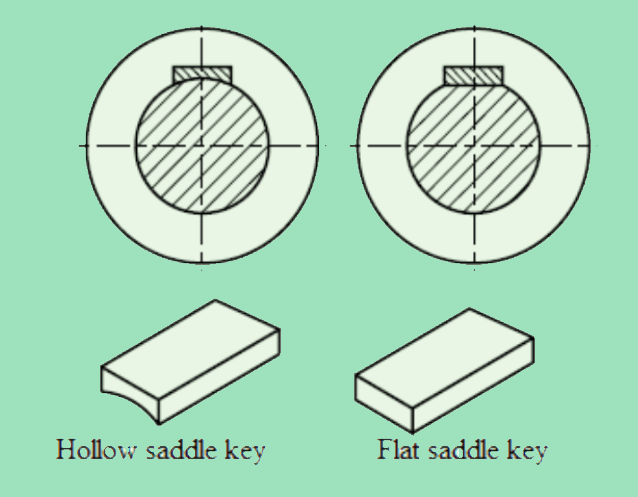

In the case of the saddle key which is the first type of key in Machine Design, the function of resisting the relative motion and transmitting the torque is obtained by the friction between the key and the shaft. So in this case, the key which has a high coefficient of friction is required. There are two types of saddle keys:

- Flat saddle Key: It is a tapper key, in which almost all the portions fit inside the hub keyway and it is flat on the shaft.

- Hollow saddle key: It is a tapper key, in which almost all the portions fit inside the hub keyway, and the bottom of the surface is curved as it fits over a curved surface of the shaft.

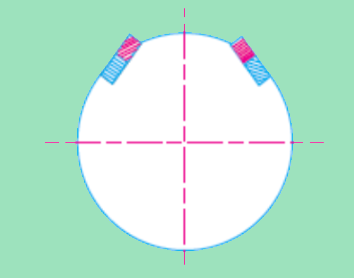

Tangent Keys

The tangent key is fitted inside the rotating shaft and the hub. It is tangential to the surface of the shaft. It is always in pairs at right angles to each other as shown in the figure.

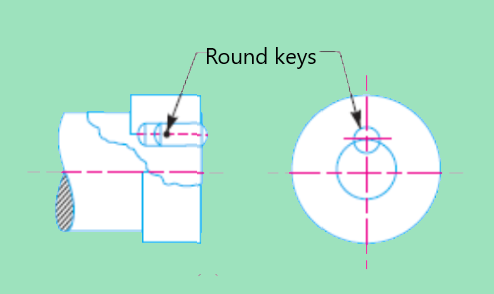

Round Keys

As the name round key, it is circular in section and fits into the rotating shaft and the hub as shown in the figure. The circular keyway is drilled and reamed after the assembling of the mating parts. It is the most suitable in the case of low-power drives.

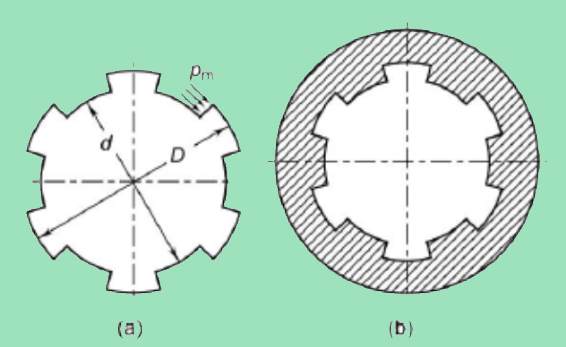

Spindle Key

The spindle key is made integral with the shaft as shown in the figure. By milling operation splines are cut on the shaft whereas broaching is done in the hub. The advantage of the design of the key is that there are relative axial motions possible between the shaft and hub.

Functions of Different Types of Keys in Machine Design

The function of various types of keys in Machine Design differs and hence they are used in different places. To prevent relative motion between the rotating shaft and the machine element like gear, flywheel, sprocket, and pulleys, keys are inserted between the rotating shaft and the boss or hub of that element there are two main functions of keys:

- The first function of the key is to transmit the torque and power from the rotating shaft to the hub of the mating element and vice versa.

- The second function of the key is to resist the relative rotational motion between the rotating shaft and mating elements like gear, flywheel, sprockets, or pulleys.

Apart from this function base on the design of the key, it resists the axial motion between the two mating elements, a feather key or splined connection can not resist axial motion

Strength of the Keys and Key Joint

As the key is inserted inside the keyway between the shaft and the hub, its portion gets sheared by both shaft and hub. While transmitting the torque and power the shear force and compressive force is applied to the keys. So key must be to have high shear crushing strength. The design of the key should be such that it must have sustained the maximum stress developed in it.

The shear and crushing stress developed depends on the shape, size, and number of keys present in the joint. As per the Indian standard steel of tensile strength of more than 600 N/mm2 shall be used as the material for the key. For safety purposes, 3-4 factors of safety should be provided.