Steel: Composition, Properties, Applications, Types, Density

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Steel is a type of material made up of Iron and Carbon. A material is generally categorized into metal, non-metal, and alloy. An alloy is a type of material that is made up of combinations of metal and non-metal both. So steel can be said that an alloy type of material as Iron is a metallic material, and Carbon is a non-metallic material. Although the carbon content in this is very low, it varies up to 2 percent. Increasing the carbon content makes it brittle in nature. Therefore, many other constituents are added to the steel to enhance its properties based on its intended purpose.

Steel is a material that is mostly used as a building material. It is the most used material in the construction industry. In Civil Engineering construction, steel is mostly used to make railway bridges, roof truss structures, etc. The steel structure is low in weight, which has many advantages over concrete structures and other structures. It has a variety of uses in the real world, from making small needles to making large tankers. Before the invention of steel, structures had been made very heavy in weight and less durable. Still, a revolution is seen in the construction industry after the invention of steel.

Download Formulas for GATE Civil Engineering – Steel Structures

Table of content

What is Steel?

Steel is an alloy material. Its major constituent is Iron and Carbon. Carbon is added to steel because it improves its durability and strength, and fracture resistance is also increased compared to Iron. Other chemicals can also be added to it based on its use; for example, stainless steel has an additional 11 % chromium, making it corrosion-resistant. It is a material with high tensile strength and an optimum cost; that’s why it is mostly used in building and other civil engineering construction. Not only in the construction industry, but it is also used for making machinery equipment and other tools.

Steel has many advantages in the construction industry, including its low weight, high strength, high durability, Resistance to corrosion, Resistance to fire, etc. Steel. For development, in this modern era of life, steel plays an important role in the world of designing structures. Steel is high malleable material with a high tensile and compressive strength. Many are confused between steel and Iron, but these two are different building materials; even iron is a constituent of steel present in a high percentage. Plain carbon steel is commonly used in construction because of its strength.

Download Formulas for GATE Civil Engineering – Engineering Mechanics

Properties of Steel

The properties of steel depend on its constituents. Its properties include many parameters like Tensile strength, Compressive strength, Yield strength, Ultimate strength, Fatigue strength, Malleability, Creep, Elongation, Ductility, Low-weight, Hardness, etc. Here some properties of steel are described in detail.

- Hardness: The property of steel tells about the resistance against abrasion and friction. Steel should be sufficiently hard enough to resist abrasion due to the effect of external load applied over it

- Toughness: A material can absorb external energy without any kind of fracture. Toughness can also be defined as the resistance of a material against the fracture when it is subjected to external loads. It is very similar to the hardness of a material, but both are different parameters.

- Yield strength is the maximum stress of material before its yielding; it can also be defined as the force required for the permanent deformation of the material.

- Tensile strength is defined as a material’s capacity to withstand tensile stresses. Steel is considered a material having high tensile strength.

- Ductility is a material’s ability to deform before the failure material. Steel is considered a ductile material. As the carbon content of steel increases, its ductility decreases.

Types of Steel

Types of steel depend on many parameters, like its strength, constituents, use, etc. Depending on its constituents, steel can be classified into the following types:

- Stainless steel

- Carbon steel

- Tool steel

- Alloy steel

These types of steel are explained below:

Stainless steel: It has an alloy of Chromium with a minimum of 11 %. It has a high corrosion resistance capacity. Due to its property, it is mostly used in home appliances. It has a high shock resistance capacity for a variety of temperature ranges.

Carbon steel: Based on the carbon content of the steel, it is categorized as high carbon content steel, Medium carbon steel, and low carbon steel or mild steel. As the carbon content of steel increases, its brittleness increases, and hence steel becomes less ductile.

Tool steel: These are made up of the alloy of Vanadium, Cobalt, Tungsten, Molybdenum, etc. These constituents make it to high resistance against heat and become more durable. They are used for the making tools like pressing, mold-making, etc.

Alloy steel: Along with the carbon content in steel, some other constituents are mixed, which makes some unique properties. These constituents can be silicon, aluminum, copper, etc. These alloy steels are useful for mechanical operations.

Download Formulas for GATE Civil Engineering – Solid Mechanics

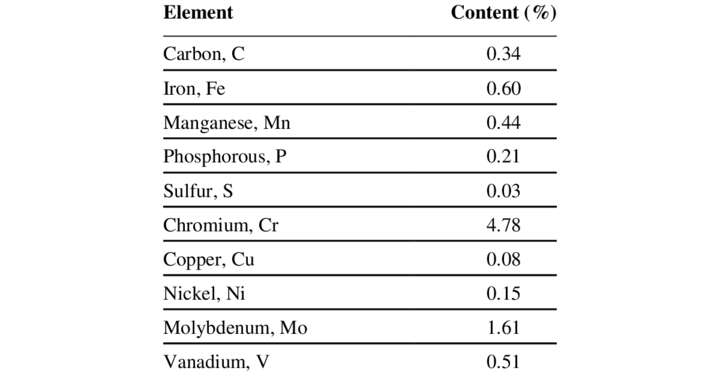

Steel Composition

Depending upon the type of steel, its composition varies; for example, based on the percentage of carbon content, it is classified as high, medium, or low carbon content steel. Likewise, different properties of steel also vary according to its compositions. Generally, steel is a composition of different materials like Chromium, Aluminum, Manganese, Iron, Phosphorus, Sulfur, Copper, Nickel, etc. Here the composition of medium carbon steel is given, which helps to understand the steel composition.

Poisson’s Ratio of Steel

The Poisson ratio is the ratio of lateral strain to longitudinal strain. Poisson’s ratio tells the material’s behavior under the axial load’s action in its transverse direction. The value of the Poisson’s ratio depends upon its constituents. Based on that, the average value of Poisson’s ratio for steel is estimated to be 0.28. And for the steel having aluminum alloys, it is 0.33. Here the Poisson’s ratio for different materials is shown below:

|

Material |

Poisson’s ratio |

|

Aluminum |

0.33 |

|

Brass |

0.34 |

|

Bronze |

0.35 |

|

Cast Iron |

0.27 |

|

Concrete |

0.20 |

|

Copper |

0.355 |

|

Steel |

0.288 |

|

Stainless steel |

0.305 |

|

Wrought Iron |

0.278 |

Applications of Steel

Uses and applications of steel depend upon its constituents and other parameters because its properties vary based on its constituents; for example, variation of carbon content in the steel affects the ductile nature of steel. Steel is used to construct buildings and railway bridges and manufacture cars and other transport accessories. It is also used in making machinery equipment. It has other different uses because of its high tensile strength and other important properties. Here are a few uses of stainless steel listed below:

- Engineering applications

- Tubular products

- Building and construction projects

- Electro and electronic equipment

- Metal goods

- Transportation goods

What is the Density of Steel?

The density of steel is one of the physical properties of steel. Density is an intensive property of a material. It is a very important parameter for the design perspective of steel. It is defined as its mass per unit volume of steel. The density of steel generally varies from 7750 Kg/m3 to 8050 Kg/m3. On average, it is expressed as 7850 kg/m3.

|

Types of Steel |

The density of Steel (Kg/m3) |

|

Carbon Steel |

7850 |

|

Alloy Steel |

7850 |

|

Stainless Steel |

8000 |

|

Tool Steel |

7695 |

Strength of Steel

The strength of steel can be expressed by its tensile strength, compressive strength, or shear strength. But generally, its strength is expressed by its tensile strength. Strength is the measure of the capacity to resist the effect of external load. Strength can be either yield strength or its ultimate strength. The yield strength of a material is defined as the capacity of a material to resist before the yielding of material, while ultimate strength is the capacity of the material before its ultimate fracture.

The strength of steel varies with its composition; for example, increasing the carbon content in steel increases its compressive strength and reduces its tensile strength by increasing the brittleness property. The strength of steel also depends upon the stress-strain relationship of different steel. The strength of stainless steel generally varies from 170 to 450 Mpa.

What are Steel Structures?

A structure is the arrangement of well-interconnected members; it may be either a stable or an unstable structure. A structure can be made of any material, but mostly concrete, and steel structures are designed in civil engineering. Concrete structures are generally used for making large structures.

Steel structures are structures made up of steel ingredients. These structures can withstand a very high amount of stress generated due to external loads. These structures are generally seen in railway bridges, roof truss structures, etc. Steel structures are light in weight and easy to construct. Because of its advantages, it is used widely in civil engineering for construction projects.

Difference Between Steel Structures and Concrete Structures

Steel and concrete structures are used in civil engineering construction works. Their use in structure is based on the suitability and requirement of the site. Concrete is a material that is strong in compression, while steel is strong in tension but can withstand compressive or shear loads. Here a few differences between these structures are listed below:

- Concrete structures are strong in compression only, while steel structures can withstand compression, tension, or shear.

- Concrete structures are constructed at the site, while steel structures are prefabricated.

- The strength of steel structures is very high compared to concrete structures.

- Steel structures are resilient, unlike concrete structures.

- Steel structures are lighter than concrete structures.