Prestressed Concrete

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Prestressed concrete is a type of concrete in which an appropriate amount and distribution of internal stress are supplied to counteract the stresses caused by external loads to the desired degree. In the concrete section, high-strength steel wire or alloys (known as ‘tendons’) are provided so they generate the initial compression. Because an initial load is applied to the structure prior to its use, prestressed concrete differs from traditional RCC structures.

Prestressing is a technique for preventing cracks, increasing the part’s strength, and reducing deflection. Prestressing is a technique for achieving a lower depth, longer span, and improved strength in a structure. Let us discuss more prestressed concrete in the upcoming sections.

Download Formulas for GATE Civil Engineering – Environmental Engineering

Table of content

What is Prestressed Concrete?

Prestressed concrete is used because, before any concrete structure breaks, fractures appear in the concrete, which is followed by the structure collapsing and cracks appearing as a result of deflection or moment. Corrosion occurs when water comes into touch with these fissures.

Prestressed Concrete Definition

Prestressed concrete is a type of concrete in which the concrete is pre-compacted before external loads are applied so that the stresses caused by external loads are counteracted in a desirable way during their service life.

Let’s understand a real example of a river bridge: if we try to build it with conventional concrete, we’ll have to raise the span’s depth, and the section will be bulky enough which means there won’t be enough space under the bridge for ships to pass.

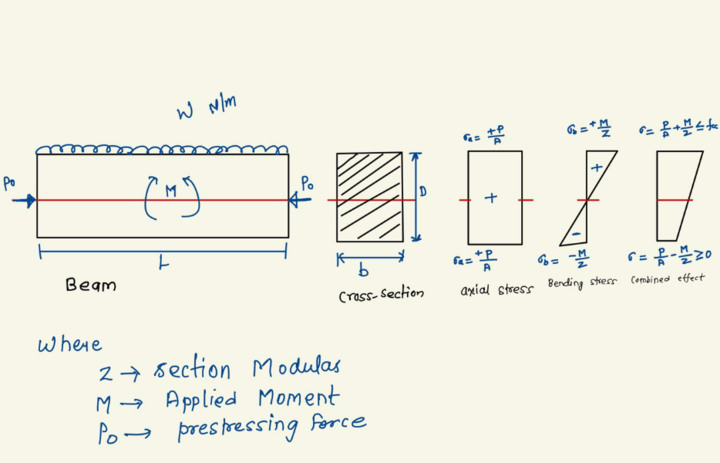

The stress balancing of the prestressed member is shown below.

Download Formulas for GATE Civil Engineering – Structural Analysis

Need of High Strength Concrete and Steel for Prestressed Concrete

Prestressed concrete requires high-strength concrete since the material is very resistant to tension, shear bond, and bearing. High-strength concrete is generally selected over cost-cutting in the zone of anchorage where bearing stresses are being imposed. High-strength concrete has a lower risk of shrinkage cracks, a lower modulus of elasticity, and a lower ultimate creep strain, resulting in less prestress loss in steel. With the use of high-strength concrete, the cross-sectional dimensions of prestressed concrete structural elements are lowered, and the material’s dead weight is reduced, allowing for a greater span to be technically and economically feasible.

If we use low-grade steel all the initial stress in it will be lost in its due course. Normally stress loss due to creep and shrinkage in long-term loss is approx. 160 N/ mm2. Hence there would not be any prestressing force remaining in the concrete, and the beam will fail. Hence to avoid failure high strength steel is used such that the initial prestress in it would be 1200 – 2000 N/ mm2.

Download Formulas for GATE Civil Engineering – Geotechnical Engineering

Types of Prestressing

Prestressing is done by tensioning the steel wires, cable, strands, or bars which are called ‘tendons’. The tendons produce initial prestressing force. The stresses in a tendon may reach up to 2000 N/mm2. Prestressing concrete can be classified in several ways, one of the important parameters is based on the construction method.

Pre-Tensioning

In this method the steel tendon is first tensioned and placed between the supports before the construction of a concrete member, the later concrete member is cast over the tendon and then the tendon is cut off at the maturity of concrete ( 28 days ), which transfers the prestressing force on the member.

- The minimum grade of concrete required for the pre-tension member is M40

- The bond between the concrete and steel is responsible for stress transfer in pre-tension members. Bonds are fully effective and hence loss in pre-stress due to friction is not present.

- The length of the tendon from each end of the pre-tensioned member to the section, where required pre-stress is achieved is called transmission length.

Post-Tensioning

The concrete member is first constructed by leaving a hollow duct along the central axis of the member. Steel tendon is provided and tensioned after the full maturity of concrete (28 days). The steel tendon is finally anchored at the ends of the member to transfer the pre-stresses on the concrete member. The space remaining in the duct is then filled by use of grouting.

- The minimum grade of concrete required in the post-tension member is M30·

- End bearing is responsible for the transfer of pre-stress in post-tension members. The bond is not effective in the post-tensioning system, which results in a loss in pre-stressed due to friction.·

- The zone of stress variation from each end of the post-tension member is known as the end block zone. The stresses along the length of the member at the ends are known as spalling stress (Compressive) and the stress transfer to the length of the member is known as bursting stress.

Other Types of Prestressing

- Thermal prestressing

- Electrical prestressing and

- Support displacement method etc.

Types of Prestressed Concrete

Prestressed Concrete can be classified based on the type of prestressing done. There are two types of prestressed concrete:

- Pre-tensioned concrete

- Post-tensioned concrete

The Post-tensioned concrete can be further divided into two parts which are:

- Bonded Post-tensioned concrete.

Unbonded Post-tensioned concrete

Disadvantages and Advantages of Prestressed Concrete

Due to its load-balancing mechanism, prestressed concrete helps in reducing the dimensions of any concrete member. The benefits and drawbacks of prestressed concrete are described further down.

Advantages of Prestressed Concrete

- A dead load of PSC members is lesser than RCC members, hence a dead load of PSC slab and beams will be lesser on a column.

- The shear resistance of PSC members is more and the concrete area is fully utilized.

- The deformation and cracks in the PSC members are much lesser than in an RCC member.

- The use of high-tensile steel to prestress concrete improves the materials’ efficiency.

- Concrete’s shear strength and fatigue resistance are improved by prestressing.

Disadvantages

- Prestressing process requires skilled labor and supervision which may result in an uneconomical structure, where the labor cost is considerable.

- Prestressing needs advanced equipment and machinery to apply to prestress on the concrete member, which may not be available at some sites.

- There is a need for quality control and inspection.

Get complete information about the GATE exam pattern, cut-off, and all those related things on the Byju Exam Prep official youtube channel.