Concrete Mix Design

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Concrete mix design is the design process of reinforced concrete structures. In the designing process of concrete structures, designing is done based on some conditions. These conditions are known as the designing parameters. Designing concrete structures has two methods: the limit state method and the working stress method. The concept of concrete mix design is used to fix the proportion of different concrete mix ingredients.

Concrete Mix Design PDF [GATE Notes]

Concrete mix design consists of various steps for finding the quantity of different concrete ingredients. Using the concrete mix design approach makes the design more economical. Concrete mix design is generally used to construct large structures because it involves large quantities of ingredients.

Download Formulas for GATE Civil Engineering – Construction Materials & Management

Table of content

What is Concrete Mix Design?

Concrete mix design is the process of determining the proportion of the different concrete ingredients. These ingredients consist of cement, sand, aggregates and water. Concrete properties depend on these ingredients. These proportions are fixed so that concrete attains its maximum strength.

Concrete mix design involves many steps, including calculations and laboratory tests. Generally, the concrete mix design approach is used to find concrete ingredients having a grade of more than M25. Finally, concrete compressive strength is determined after 28 days of the casting of concrete material.

Concrete Mix Design IS Code

Concrete mix design is the process of finding the different ingredients of the concrete mix. The process for designing concrete mix. With the help of concrete mix designing quantity of concrete ingredients can be determined. The process of determining these ingredients is given in IS 10262.

IS 10262 explains the proper procedure for determining the different ingredients of concrete. After properly preparing the design mix with the help of IS 10262, concrete structures will be prepared according to IS 456. IS 456 properly explains the procedure of designing and detailing concrete structures.

Download Formulas for GATE Civil Engineering – Engineering Mechanics

Classification of Concrete Mix Design

Classification of concrete mix design is based on different parameters. These parameters govern the strength of the concrete. Here some classifications of concrete mix design are listed below. These classifications are based on some parameters.

Based on Cementing Material

Concretes are classified as lime concrete, gypsum concrete, and cement concrete.

Based on Perspective Specification

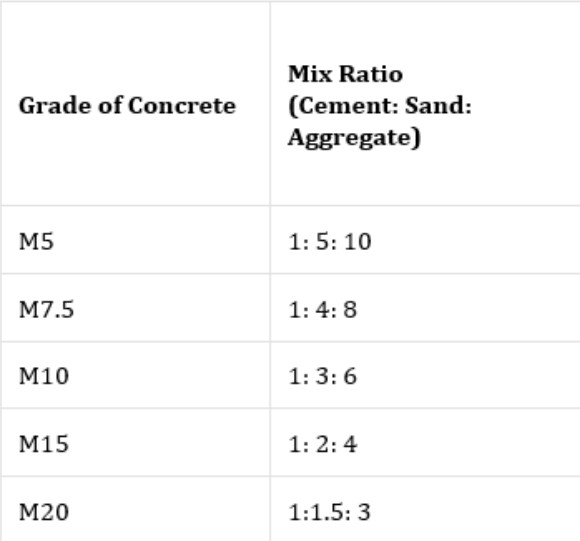

The cement concrete is specified by proportions of different ingredients, e.g., 1 (cement): 1.5 (fine aggregate) : 3 (coarse aggregate). The following table shows the usual mix proportions of the cement concrete. Where M denotes the mix. This type of concrete mix is known as the nominal mix. Conventional nominal mix proportions have limited significance since the quantity of fine aggregate is fixed irrespective of the cement content, water-cement ratio and the maximum aggregate size to be used. The proportions of nominal mixed concrete materials, as given in Table, are prevalent in the field. But according to the IS 456 code of RCC design, only the M-20 grade of concrete is suitable for such use.

|

Grade of concrete |

M10 |

M15 |

M20 |

M25 |

|

Mix proportion |

1:3:6 |

1:2:4 |

1:1:1/2 :3 |

1:1:2 |

|

Perspective characteristic Strength |

10 |

15 |

20 |

25 |

Based on Performance-Oriented Specification

Based on the performance of the concrete material, like strength and other characteristics, it is classified into the following types.

|

Grade |

M5 |

M7.5 |

M10 |

M20 |

M25 |

M30 |

M35 |

M40 |

M45 |

M50 |

M55 |

|

Characteristic strength |

5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

45 |

50 |

55 |

Based on Bulk Density

Based on density, concrete is classified as super heavy (over 2500 kg/m3), dense (1800-2500 kg/m3), lightweight (500–1800 kg/m3), and extra lightweight concrete (below 500 kg/m3)

Download Formulas for GATE Civil Engineering – Solid Mechanics

Based on Place of Casting

When concrete is made and placed at the site, it is known as in-situ concrete, and when used as a material for making prefabricated units in a factory, it is known as precast concrete.

Concrete Mix Design Ratio

The concrete mix design ratio shows the proportion of the different concrete ingredients. These ingredients are cement, aggregates and sand. These ingredients are mixed together in a fixed proportion for a particular concrete mix.

Methods of Concrete Mix Design

Different concrete mix design methods are based on certain parameters. These parameters may be the designing procedure, purpose of designing, etc. Here a few methods of concrete mix designing are listed below.

- The American method of mixed design

- Graphic method of mixed design

- Mix design by Indian standard method

- American concrete institute method of mix design

- A rapid method of mixed design.

|

Other Important GATE Notes |

|