- India’s GDP for the first quarter of 2020-21 contracted by 23.9%, and the share of the manufacturing sector in total gross value added (GVA), which was 17.5% in quarter 1 of 2019-20, shrunk to 13.8% in this quarter.

- The growth rate in the manufacturing sector plunged to-39% in 2020-21. For eight consecutive quarters from the previous year and this year, waves of covid 19 manufacturing growth rate have declined, indicating a lack of demand and a deeper structural crisis in the sector worsened by the pandemic-induced lockdowns and less money spent by people on the manufacturing industry products.

- This daily lockdown has severely decreased the demand rate, which has also affected the heavy machinery import of the country.

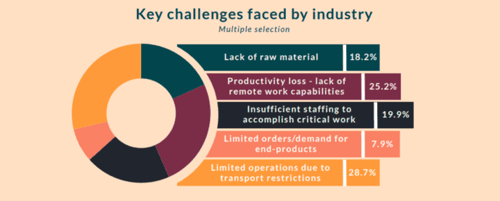

Key Challenges faced by India's Manufacturing sector due to covid

- Lockdown -COVID-19 creates a high degree of uncertainty in Manufacturing processes. In particular, the need to avoid the further spread of the virus in the area, the workplace, or through the movement of people and materials results in further restrictions and a potential return to lockdown.

- Market Slow Down - Even when markets reopen post-lockdown, unexpected cash flow slows down. This is largely due to extreme uncertainties about the demand for MSMEs products, and always a question arises whether they will be able to cope with new demand and supply.

- Manpower -Manpower also becomes a constraint, with MSMEs indicating that 30 to 70 percent of their pre-COVID-19 workforce may have migrated back to their hometowns due to uncertainties and loss of income during the lockdown due to the sudden closure of industry. It is always a challenge to convince staff to return or hire new staff, and the staff turnover is expected to negatively impact productivity and quality, adding further to financial concerns when manufacturers are again planning to open the industry.

- Machinery and Raw Materials - Small and Large manufacturing units will have to undertake outstanding maintenance and service and clean out wasted stocks to resume operations at full capacity.

- Supply and Demand Breakdown - Ensuring timely supplies of essential goods and raw materials without price hikes is a huge matter of concern. Those small units that are critically dependent on specialized parts from other states or from abroad express concerns about their vulnerability to supply shortages

MANUFACTURING PRODUCTIVITY POST COVID-19

- While manufacturing organizations are continuously working towards keeping their workers safe in this second covid wave, along with dealing with increased uncertainties and keeping productivity at its best possible, it would be better if we should be get prepared once this deadly virus leaves us.

- The pandemic gone will certainly be a piece of very good news, but how does the manufacturing industry function for better productivity after that, and does it go back to its old ways? After COVID-19, the industry’s first priority must be improving automation across its value chain, taking digital initiatives to the next level, and working as a promotion from home, especially for the support functions like HR and finance can easily be tried to make work from home and make our preparedness if the next wave arrives.

- To enhance production after the coronavirus pandemic leaves us away, all the manufacturers should also develop local suppliers for the raw materials and reduce complexity in manufacturing through standardization.

- Few MSMEs are considering further measures such as the installation of sanitization tunnels, pre-restart fumigation of factory premises, or rearrangement of workstations to maintain physical distancing, whereas Some industries expect that they will have to reduce production and call even halve staff numbers which may need to make alternative arrangements for providing food and drink at work.

- There is a general belief that the future new normal will be different from what it used to be in the past waves faced by the country. The time required to achieve some normalcy is expected to be significant, with minimum estimates varying between six weeks and six months. It will depend heavily on COVID-19 and globally in the coming weeks.

How to register Yourself for vaccine

Comments

write a comment