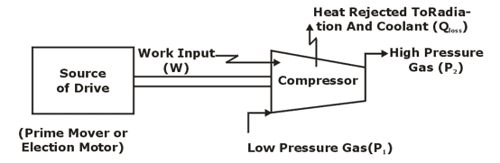

According to the Second Law of Thermodynamics, this is only possible when the work is done on the gas by an external agency, such as prime movers, electric motors, etc.

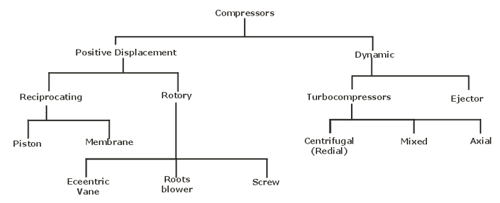

Classification of Compressors

On the basis of design and principles of operation

On the basis of final pressure

- Low-pressure compressors - final pressure does not exceed 10 bar.

- Medium pressure compressors – final pressure with a 'range 10 bar to 80 bar.

- High-pressure compressor - final pressure with a range 80 to 1000 bar.

On the basis of pressure rise limit

- Fan, Pressure ratio <1.1.

- Blower, Pressure ratio >1.1<2.3.

- Compressor, Pressure ratio >2.3

Reciprocating compressors:

- In this compressor, the gas volume decreases, and pressure increases due to the action of one or more reciprocating piston moving axially in one or more cylinders.

- It may he single acting or double acting, single cylinder or multi cylinder, single stage, or multi-stage.

- It is widely used. in the refrigeration system such as freeze, air conditioner and cold storage, mining works, chemical factories, fertilizers factories, garages etc.

Single Stage Reciprocating Compressor Without Clearance:

Consider a single-stage, single acting, ideal reciprocating compressor having no flow resistance at suction or delivery valve, no clearance.

Single Stage Compressor with Clearance:

In actual compressor there is a small clearance between the cylinder head and piston for thermal expansion, machine tolerance and for preventing the piston striking the cylinder head.

Clearance volume: It is the volume occupied by the cylinder head and piston when the piston is at the top (i.e. at the inner dead center).

Swept or displacement volume: The displacement volume or swept volume Vs is defined as the volume swept by the piston in one stroke.

The clearance ratio, C is defined as the ratio of clearance volume, Vc to the swept volume Vs.

Volumetric Efficiency: The ratio of the actual volume sucked to the volume swept by the piston is known as the volumetric efficiency.

Free air delivery (FAD): Delivery volume reduces to 1 bar pressure & 15°C temperature. The Corresponding volume is known as free air delivered. With the use of free air delivered we can compare the handling capacity of different compressors working under different conditions.

Rotary Compressors

Rotary compressors are compressors gas to high pressure due to a decrease in volume of gas (more specifically due to push and pull of gas or squeezing action of the gas) by the rotary movement of a single rotor or multiple rotors. Rotary compressors are suitable for low compression ratio up to 11 bar and for small and medium amounts of free gas delivered.

Centrifugal compressors: The centrifugal compressor consists of an impeller with a series of curved radial vanes housed in a stationary casing. The impeller imparts a high velocity to the air which firms through fixed divergent passages, in which air is decelerated with a consequent increase in static pressure. The main components of the compressor are:

- inlet pipe

- impeller

- diffuser (vaneless or with vanes)

- volute casing, and

- outlet pipe.

Principle: Let us assume the fluid enters at section (1) & leaving at section (2) at a radius r1 & r2. Under equilibrium condition it is running at a constant angular velocity of ω then the absolute velocity component can be resolved into two components i.e.

V1coα = whirl component/tangential/component

& V1sinα = Flow component/radial component

Rotor speed at inlet (u1) = r1ω

Rotor speed at exit (u2) = r2 ω

Angular momentum at section (1) = mVw1r1

Angular momentum at section (2) = mVw2 r2

Torque = Rate of change of Angular momentum:

![]()

For Compressor or pump because outlet fluid is having more energy as compare to inlet

Velocity triangles at inlet and outlet: Let us assume α is a nozzle angle or the absolute velocity angle at the inlet.

β: Absolute velocity angle at outlet/diffuser inlet angle.

θ & ϕ are the moving blade angle at inlet & outlet.

Vr: Relative Velocity: It is the velocity of water along the surface of the vane.

![]() : is termed as impulse effect. It represents the increases in K.E. of the working fluid that needs to be converted into pressure rise in the diffuser.

: is termed as impulse effect. It represents the increases in K.E. of the working fluid that needs to be converted into pressure rise in the diffuser.

![]() : Centrifugal effect: It represents the rise in pressure in working fluid as fluid enters at a smaller diameter & leaving at a larger diameter.

: Centrifugal effect: It represents the rise in pressure in working fluid as fluid enters at a smaller diameter & leaving at a larger diameter.

![]() : Reaction or diffusion effect: It represents the rise in static pressure as the flow is taken place in diverging passage due to which its relative velocity decreases from inlet-outlet.

: Reaction or diffusion effect: It represents the rise in static pressure as the flow is taken place in diverging passage due to which its relative velocity decreases from inlet-outlet.

Axial flow compressors

- The axial flow compressor is more efficient and is usually preferred for bigger units with high-pressure ratios applications such as industrial and large gas turbine plants.

- Although some units may have two or more centrifugal compressors with intercooling between stages.

Velocity triangle for the rotor and stator of an axial flow compressor

Degree of Reaction: It is defined as the ratio of enthalpy rise across moving blade to the enthalpy rise across the stage.

Comparison between Centrifugal and Reciprocating Compressors

Reciprocating | Centrifugal |

(i) Presence of reciprocating masses makes the machine unbalanced and hence vibration problems are greater. | (i) Absence of reciprocating masses makes the machine better balanced. |

(ii) Presence of numerous sliding or bearing members lowers its mechanical efficiency. | (ii) Absence of numerous sliding or bearing members improves its mechanical efficiency. |

(iii) Higher installation cost. | (iii) Lower installation cost. |

(iv) Pressure ratio per stage is high, about 5 to 8. | (iv) Pressure ratio per stage is about 3 to 4.5. |

(v) Capability of delivering high pressure. By multi staging, high delivery pressure up to 5000 atm may be achieved. | (v) Capable of delivering medium pressure. By multistage, the delivery pressure up to 400 atm may be achieved. |

(vi) Capable of delivering small volume. By using multi-cylinder, the volume may be increased | (vi) Capable of delivering greater volumes per unit of building space. |

(vii) Greater flexibility in capacity and pressure range | (vi) No flexibility in capacity and pressure range. |

(viii) Higher maintenance expense. | (viii) Lower maintenance expense. |

(ix) Higher compression efficiency at compression ratio above 2. | (ix) Higher compression efficiency at compression ratio less than 2. |

(x) There is always a chance of mixing working fluid with lubricating oil. | (x) No chance of mixing of working fluid with lubricating oil. |

(xiv) Suitable for low, medium, and high pressure and low and medium gas volumes. | (xiv) Suitable for low and medium pressure and large gas volumes. |

You can avail of BYJU’S Exam Prep Online classroom program for all AE & JE Exams:

BYJU’S Exam Prep Online Classroom Program for AE & JE Exams (12+ Structured LIVE Courses)

You can avail of BYJU’S Exam Prep Test series specially designed for all AE & JE Exams:

BYJU’S Exam Prep Test Series AE & JE Get Unlimited Access to all (160+ Mock Tests)

Thanks

Team BYJU’S Exam Prep

Download BYJU’S Exam Prep APP, for the best Exam Preparation, Free Mock tests, Live Classes.

Comments

write a comment