Casting

Casting is one of the oldest manufacturing processes, and even today is the first step in manufacturing most products.

“In a casting process, the liquid molten metal is poured into the mould cavity having the similar shape of the casting to be produced, & left free it to solidify and after solidification, the casting can be taken out by breaking the mould".

A Pattern is the replica of the part to be cast (to be produced) and is used to prepare the mould cavity. Patterns are made of either wood or metal.

An assembly of two or more metal blocks, or bonded refractory particles (sand) consisting of a primary cavity is called mould.

Advantages of Casting

- Molten metal can flow into any small section in the mould cavity, hence any intricate shape can be produced.

- Practically any material can be casted.

- Tools required are very simple and inexpensive.

- Due to same cooling rate from all directions, the uniform mechanical properties can be obtained.

Pattern Allowance - A pattern is always slightly different from the final job to be Produced. This difference in dimensions is referred as the pattern allowance.

Pattern size = casting size ± allowances

Shrinkage Allowance

- Liquid Shrinkage

- Solidification Shrinkage

Solid shrinkage

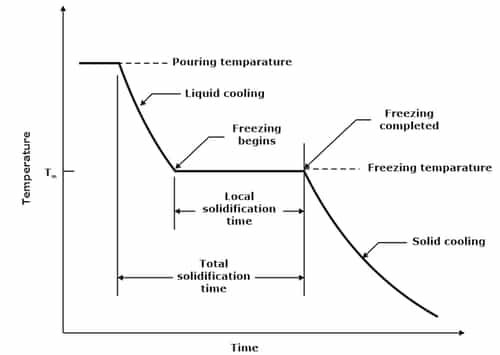

Fig.1: Cooling curve for a pure metal during casting.

Solid shrinkage,

Shrinkage allowance to be provided on pattern

![]()

Where, δL=Change in dimension

L = Initial dimension of component

α = Coefficient of thermal expansion

Machining Allowance:

The Typical machining allowances for sand castings range = 1.5 mm and 3 mm

Draft or Taper Allowance:

A draft facilitates easy withdrawal of the pattern. The value of the draft is between 0.5° and 2°.

Shake Allowance:

Allowance provided on the pattern to compensate this increase in size of the casting is known as shaking Allowance.

Distortion Allowances:

To avoid the distortion, the shape of pattern itself should be given a distortion of equal amount in the opposite direction of the likely distortion direction so that final product will come in true shape known as distortion allowance.

Types of Patterns

(i). Solid or single piece pattern:

It is the simplest pattern in which pattern is made up of single piece and it does not contain any attached part.

(ii). Split Pattern or Two-Piece Pattern

This pattern is used mainly for intricate castings.

(iii). Match plate pattern

Production efficiency and dimensional accuracy is improved by this method.

(iv). Cope and drag pawn:

The cope and drag halves of a split pattern are separately mounted on two match plates. Thus, the cope and the drag flasks are made separately and brought together (with accurate relative location) to produce the complete mould.

(v). Gated Pattern:

This is simply one or more than one loose pattern with attached gates and runners and provides a channel through which the molten metal can flow from the pouring sprue to the mould cavity.

(vi). Loose Piece Pattern:

In this pattern, the parts of the pattern will overhang such that It is not possible to remove the pattern from the sand, in any direction, even if parted.

(vii). Sweep pattern:

Sweep patten is used to generate surfaces of revolution in large castings, and to prepare moulds & it is done by sweeping the complete casting by means of a plane.

(viii). Follow board pattern:

It is used for castings where having structurally weak portions and are likely to break under the force of ramming if not supported.

(ix). Skeleton Pattern:

This type of pattern is useful generally for very large castings required in small quantities where large expense on complete wooden pattern is not justified.

Effect of moisture content on properties of moulding sand:

Properties of Moulding Sand

(i). Permeability:

It is the ability of moulding sand to allow the air to escape”. It is important to remove the gases because the gases trapped inside the casting cause defects.

The permeability number is given by:

![]()

Where,

V= volume of air in cm3

H = height of the sand specimen in cm

P = air pressure, gm/cm2

A = Cross section area of sand specimen in cm2

T = time in minutes,

Where, T is in minute

(ii). Strength:

Measurement of strength of moulding sands can be carried out on the universal sand strength testing machine.

(iii). Green Strength:

The strength of the moist moulding sand is termed as green sand.

(iv). Dry Strength:

When the moisture in the moulding sand is completely removed, it is called dry sand.

(v). Hot Strength:

The strength of the sand that is required to hold the shape of the mould cavity is called hot strength.

(vi). Refractoriness:

The ability of with standing higher temperature of the molten metal so that it does not cause fusion i.e. without losing its strength and hardness is called refractoriness.

(vii). Mould Hardness:

Hardness is opposite to permeability. Higher the permeability number lower will be the hardness and vice versa.

(viii) Cohesiveness:

The ability to form bond between same material particles is called as cohesiveness.

(ix) Adhesiveness:

The ability of bond formation of sand particles with other materials is called adhesiveness.

(x) Collapsibility:

Collapsibility is the property of material due to which, it does not provide any resistance during the contraction of the solidified casting.

(xi). Flowability:

The ability of flowing of moulding sand into each and every corner of the mould is called flowability. Cavities and hollow projections, which are difficult to produce using the pattern alone, are produced with the help of core.

Core print:

Recess provided in the mould for locating, positioning and supporting of cores is called core print.

Fig.: buoyancy force on Core

Net buoyancy force acting on the core = Weight of liquid displaced due to projected portion —total weight of Core.![]()

Chaplets:

Metallic supports, which are kept inside the mould cavity to support the cores, are called chaplets.

Chaplets have the same composition as that of the pouring metal thus enough heat is present from the molten metal to completely melt them and thus fuse with it during solidification.

Chills:

Chills are metallic objects which is placed in the mould to increase the cooling rate of castings to provide uniform or desired cooling rate.

PADS OR PADDING

At the corner, due to improper ramming, there is always chances of erosion of sand When the molten metal is filled in mould cavity.

To avoid this, some objects are provided at the corner to support the mould which is known as pad & this process is known as padding.

Gating Ratio:

The gating ratio refer to the proportion of the cross-sectional areas between the sprue, runner and in-gates, and is generally denoted as sprue area, runner area, and ingate area.

Gating ratio = Ratio of (sprue area: runner area: ingate area)

Gating ratio = AS: AR: AG

Casting Yield:

The casting yield is the proportion of the actual casting mass, m, to the mass of metal poured into the mould M.

![]()

Choke Area:

It is also the minimum area in whole gating system (sprue area, runner area, ingate area).

where H = effective metal head (sprue height), mm

Non-pressurized Gating System:

A non-pressurized gating system has choke area (minimum area) at the bottom of the sprue base and have total runner area and in-gate areas higher than the sprue area.

Pressurized Gating System:

In this system, the smallest area is the in-gate area and thus it maintains a back pressure throughout the gating system.

Top Gating System

In top gating, the liquid metal is poured directly from the sprue to mould cavity with atmospheric pressure at the base.

Pouring or filling time for Top Gating:

Bottom gating system:

where,

ht =total height

hm=height of the mould

Special case:

If height of the mould(hm) is equal to total height (ht).

![]()

Solidification time:

“It is the time required for the casting to solidify after pouring” and this time is dependent on the size and shape of the casting.

Solidification time is given by Chvorinov's rule:

Where,

ts = total solidification time

k = mould constant (or) solidification factor

V = volume of the casting,

SA = surface area of the casting,

MODULUS:

It is the ratio of volume to surface area of any casting. This formula is applicable for risers also.

Methods of Riser Design

Caine’s Method:

This method can be used to calculate the dimensions of the Riser for the simple shape of the castings.

Shape factor method:

![]()

SPECIAL CASTING PROCESSES:

Shell moulding

Shell moulding is a casting process in which the mould is a thin shell (typically 9 mm) made of sand held together by a thermosetting resin binder.

The thickness of the shell can be determined accurately by controlling the time that the pattern is in contact with the mould.

Fig.: Steps in shell-moulding

Investment casting:

(i) In investment casting, a pattern made of wax is coated with a refractory material to make the mould, after which the wax is melted away prior to pouring the molten metal.

(ii) The term Investment comes from one of the less familiar definitions of the word Invest, which is "to cover completely," this referring to the coating of the refractory material around the wax pattern.

Advantages of investment casting:

(i). parts of great complexity and intricacy can be cast

(ii). Close dimensional control—tolerances of ±0.075 mm, are possible.

(iii). Good surface finish is possible.

Applications:

(i) All types of metals. including steels, stainless steels, and other high-temperature alloys, can be investment cast.

(ii) Examples of parts include complex machinery parts, blades. and other components for turbine engines, jewellery, and dental fixtures.

Permanent-Mould Casting Processes:

In this section. permanent-mould casting is treated as the basic process in the group of casting processes that all use reusable metal moulds.

Other members of the group include die casting and centrifugal casting.

Slush casting:

Slush Casting Slush casting is a permanent mould process in which a hollow casting is formed by inverting the mould after partial freezing at the surface to drain out the liquid metal in the center.

Vacuum Permanent-Mould Casting:

The general configuration or the vacuum permanent-mould casting process is like the low-pressure casting operation. The difference is that reduced air pressure from the vacuum in the mould is used to draw the liquid metal into the cavity, rather than forcing it by positive air pressure from below.

Die casting:

Die casting is a permanent-mould casting process in which the molten metal is injected into the mould cavity under high pressure. Typical pressures are 7 to 350 MPa.

There are two main types of die-casting machines:

(i). Hot chamber die casting

(ii). Cold chamber die casting

Hot chamber die casting:

In hot-chamber machines, the metal is melted in a container attached to the machine, and a piston is used to inject the liquid metal under high pressure into the die. Typical injection pressures are 7 to 35 MPa.

The process is therefore limited in its applications to low-melting-point metals that do not chemically attack the plunger and other mechanical components. The metals include zinc, tin, lead, and sometimes magnesium.

Cold chamber die casting:

In cold-chamber die-casting machines, molten metal is poured into an unheated chamber from an external melting container, and a piston is used to inject the metal under high pressure into the die cavity.

Cold-chamber machines are typically used for casting aluminum, brass, and magnesium alloys. Low-melting-point alloys (zinc, tin, lead) can also be cast on cold-chamber machines, but the advantages of the hot-chamber process usually favor its use on these metals.

Advantages of die casting:

(i). high production rates possible:

(ii). economical for large production quantities

(iii). close tolerances possible, on the order of ±0.076 mm for small parts.

(iv). Good surface finish

Limitation of die casting:

In addition to the metals cast, is the shape restriction. The part geometry must allow for removal from the die cavity.

Centrifugal casting

Centrifugal casting refers to several casting methods in which the mould is rotated at high speed so that centrifugal force distributes the molten metal to the outer regions of the die cavity. The group includes:

(i). True centrifugal casting

(ii). Semi centrifugal casting

(iii). Centrifuge casting

Centrifuge Casting

In centrifuge casting, the mould is designed with part cavities located away from the axis of rotation, so that the molten metal poured into the mould is distributed to these cavities by centrifugal force.

Casting Defects

(i). Misruns

(ii). Cold Shuts

(iii). Shrinkage cavity

(iv). Micro porosity

(v). Hot tearing

(vi). Sand blow

(vii). Pinholes

(viii). Sand wash

(ix). Scabs

(x). Penetration

(xi). Mould shift

(xii). Core shift

(xiii). Mould crac

Comments

write a comment