Joints: Joints are temporary and permanent in nature. Permanent joints are further categories in welded joints and Riveted joints.

Advantages of riveted joints over welded joints:

- More reliable in applications subjected to vibrations and impact forces

- Riveted joints can be used for non-ferrous metals like aluminum alloy, copper, brass etc.

- Less damage to the connected parts when the joint is dismantled

Desirable Properties of Rivets

- The rivet should be sound, free from cracks, flaws, burrs, seams, pits and other defects

- The head of the rivet should be concentric with the axis of the shank

- The end of the rivet should be square with respect to the axis

Terminology of Riveted Joints:

Pitch (p): Distance between the center of one rivet to the center of the adjacent rivet in the same row.

Margin (m): distance between the edge of the plate to the centerline of the rivets in the nearest row.

Transverse pitch (back pitch or row pitch): The distance between two consecutive rows of rivets in the same plate is termed as transverse pitch.

Diagonal pitch: The center distance between one rivet and it's adjacent rivet located in the adjacent row is called as diagonal pitch.

Strength of riveted joint: The strength of riveted joint is the force that the joint can carry without causing joint failure.

Shear strength of the riveted joint:

Shear strength of the riveted joint is:

In case of double-strap single-riveted butt joint, the rivets are subjected to double shear as shown below:

Shear strength of double-riveted lap joint:

![]()

Tensile strength of plate between rivets:

Crushing strength of the riveted joint:

The failure occurs results if compressive stress between the shank of the rivet and the plate is more than the the yield stress in compression.

The crushing strength is given by:

Efficiency of the riveted joint:

- It is the ratio of the strength of riveted joint to the strength of unriveted solid plate.

- The strength of solid plate having width same as the pitch (p) and thickness (t), acted to tensile force, is given by:

Bolted Joint analysis: A bolted joint subjected to tensile force P is shown in figure:

Eccentrically loaded bolted joint in shear: An eccentrically loaded bolted connection is shown in figure

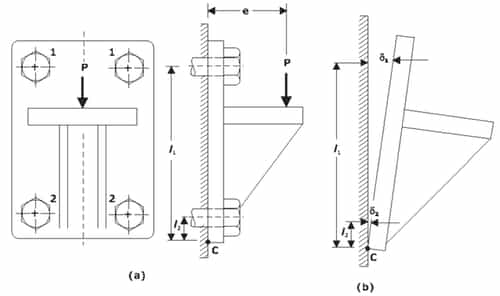

Eccentric load perpendicular to axis of the bolt: A bracket, fixed to the steel structure by means of four bolts, is shown in figure:

The bolt 1 is acted to maximum force i.e. farthest located bolt from the tilting edge C is subjected to maximum force.

The direct shear stress of the bolt is:

The tensile stress of the bolt is:

The maximum principal stress theory or maximum shear stress theory is used for the design of the bolts. Thus:

The maximum principal stress is given by:

Welded Joints: Welding is a joining process of metallic parts by heating to a suitable temperature with or without the application of pressure and with or without of filler metal.

Stress relieving of welded joints: One of the major disadvantage of the welded joints is that it is subjected to residual stresses due to non-uniform heating of the parts being joined.

The following two methods can reduce the residual stresses:

- Preheating of the weld area to retard cooling rate of the metal in the vicinity of the joint

- Stress relieving of weld area by using proper heat treatment such as normalizing and annealing in temperature range of 550 to 675°C.

Strength of Butt welds: A butt welded joint, subjected to tensile force P, is shown in figure:

Strength of parallel fillet welds: A parallel fillet weld subjected to a tensile force P is shown in the figure:

The cross-section of the fillet weld has a right-angled triangle with two equal sides. The length of each of the two equal sides is known as a leg.

Leg length = plate thickness.

The throat represents the minimum cross-section of the weld generally located at 45° to the leg dimension. Therefore:

The fillet weld failure occurs along the minimum cross-section i.e. the throat due to shear.

Strength of the transverse fillet welds: A transverse fillet weld subjected to a tensile force P is shown in figure:

The failure due to tensile stress occurs at the throat section due to being cross section area minimum. The cross-sectional area at the throat is

The tensile stress in the transverse fillet weld is given by:

The plane of maximum shear stress is inclined at an angle of 67.5° to the leg dimension.

Axially loaded unsymmetrical welded joints:

Sections having unsymmetrical welded joints such as angle or T-sections are welded to the steel plates or the beams as shown in figure. G is the center of gravity of the angle section:

The external force acting on the joint passes through G and the resisting forces in the welds 1 and 2 respectively:

![]()

The FBD of forces acting on the angle section having two welds are shown in the figure:

Eccentric load in the plate of welds: A bracket having two fillet welds is acted with an eccentric force P has been shown in figure:

The primary shear stress due to the eccentric shear stress:

![]()

where A = throat area of all welds

The couple M resulted from the eccentric load causes torsional shear stresses in the throat area of welds and resulted secondary shear stresses are:

At any point, the resultant shear stress is vector addition of primary and secondary shear stresses.

Welding joint subjected to bending moment:

A cantilever beam having rectangular cross-section welded by two fillet welds W1 and W2 as shown in figure below:

The eccentric force P can be substituted by an equal and similarly directed force (P) acting through the center of gravity (G) along with a couple is given by:

Welding joint subjected to torsional moment:

The shear stress generated in the circumferential fillet weld due to the torsional moment is given by:

where Mt = Applied torque

r = radius of the shaft

t = throat thickness.

Maximum shear stress in the parallel fillet weld: The maximum shear stress occurs at θ = 45° and it is given by:

Maximum shear stress in the transverse fillet weld:

The maximum shear stress occurs at θ = 67.5° and it is given by:

You can avail of BYJU’S Exam Prep Online classroom program for all AE & JE Exams:

BYJU’S Exam Prep Online Classroom Program for AE & JE Exams (12+ Structured LIVE Courses)

You can avail of BYJU’S Exam Prep Test series specially designed for all AE & JE Exams:

BYJU’S Exam Prep Test Series AE & JE Get Unlimited Access to all (160+ Mock Tests)

Thanks

Team BYJU’S Exam Prep

Download BYJU’S Exam Prep APP, for the best Exam Preparation, Free Mock tests, Live Classes.

Comments

write a comment