This article contains basic notes on "Flow-through Pipes" topic of "Fluid Mechanics & Hydraulics" subject.

Flow-through Pipes

Major Loss: It is calculated by Darcy Weisbach formulas

Loss of head due to friction

where,

L = Length of pipe,

v = Mean velocity of flow

d = Diameter of pipe,

f = Coefficient of friction

friction factor

friction factor

For turbulent flow, coefficient of friction

Chezy’s Formula: In fluid dynamics, Chezy’s formula describes the mean flow velocity of steady, turbulent open channel flow.

v= c √mi, c= Chezy's Constant = √(8g/f)

v= c √mi, c= Chezy's Constant = √(8g/f)

i = Loss of head per unit length of pipe

![]() (hydraulic slope tan θ)

(hydraulic slope tan θ)

m = Hydraulic mean depth

![]()

Relation between Coefficient of Friction and Shear Stress

We get ![]()

where,

f = Coefficient of friction

τ0 = Shear stress

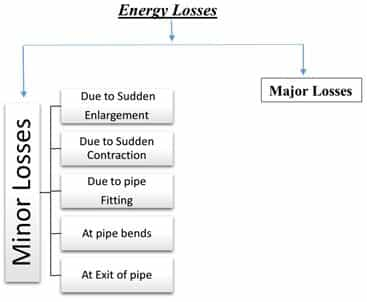

Minor Loss:

The another type of head loss in minor loss is induced due to following reasons

Loss due to Sudden Enlargement

Head loss

Loss due to Sudden Contraction

Head loss, hL = 0.5 v22/ 2g

Remember v2 is velocity at point which lies in contracted section.

Loss of Head at Entrance to Pipe

Head loss,

Loss at Exit from Pipe

Head loss,

Note: In case 1 and 2, flow occurs between pipe to pipe, while in case 3 and 4, flow occurs between tank and pipe. We are taking entry or exit w.r.t. pipe. So, be careful.

Combination of Pipes: Pipes may be connected in series, parallel or in both. Let see their combinations.

Pipe in Series: As pipes are in series, the discharge through each pipe will be same.

Q = A1v1 = A2v2 = A3v3

Total loss of head = Major loss + Minor loss

![]()

Major loss = Head loss

due to friction in each pipe

While, minor loss = Entrance loss + Expansion loss + Contraction loss + Exit loss

If minor loss are neglected then,

Pipes in Parallel: In this discharge in main pipe is equal to sum of discharge in each of parallel pipes.

Hence, Q = Q1 + Q2

Loss of head in each parallel pipe is same

where, ![]() and

and ![]() are head loss at 1 and 2 respectively.

are head loss at 1 and 2 respectively.

Equivalent Pipe: A compound pipe which consists of several pipes of different lengths and diameters to be replaced by a pipe having uniform diameter and the same length as that of compound pipe is called as equivalent pipe.

(where, L = L1 + L2 + L3)

If f = f1 = f2 = f3

Then,

Hydraulic Gradient Line (HGL) and Total Energy Line (TEL)

HGL → It joins piezometric head (p/ρg + z) at various points.

TEL → It joins total energy head at various points:

{(p/ρg + z) + v2/2g}

Note: HGL is always parallel but lower than TEL.

Power Transmission through Pipe (P)

Power delivered by a given pipe line is maximum when the flow is such that one third of static head is consumed in pipe friction. Thus, efficiency is limited to only 66.66%

Maximum efficiency, ![]()

Water Hammer: When a liquid is flowing through a long pipe fitted with a vale at the end of the pipe and the valve is closed suddenly a pressure wave of high intensity is produced behind the valve. This pressure wave of high intensity is having the effect of hammering action on the walls of the pipe. This phenomenon is known as water hammer.

Intensity of pressure rise due to water hammer,

![]()

When valve is closed gradually when valve closed suddenly with rigid pipe.

![]()

When valve closed suddenly with plastic pipe

If the time required to close the valve

![]() Valve closure is said to be gradual.

Valve closure is said to be gradual.

![]() The valve closure is said to be sudden.

The valve closure is said to be sudden.

Where,

L = Length of pipe

D = Diameter of pipe

C = Velocity of pressure wave produced due to water hammer ![]()

v = Velocity of flow

K = Bulk modulus of water

E = Modulus of elasticity for pipe material.

t = Time required to choose the valve.

Boundary-Layer Theory

Boundary Layer Theory

When a real fluid flows over a solid body, the velocity of fluid at the boundary will be zero. If boundary is stationary. As we move away from boundary in perpendicular direction velocity increases to the free stream velocity. It means velocity gradient ![]() will exist.

will exist.

Note:

Velocity gradient ![]() does not exist outside the boundary layer as outside the boundary layer velocity is constant and equal to free stream velocity.

does not exist outside the boundary layer as outside the boundary layer velocity is constant and equal to free stream velocity.

Development of Boundary Layer: Development of boundary layer can be divided in three regions: laminar, transition, turbulent.

Reynolds number

![]()

For laminar boundary layer

(Re)x < 5 × 105 (For flat plate) and if (Re)x > 5 × 105

where Re = Reynolds's number

Then, flow is turbulent.

Here, x is distance from leading edge in horizontal direction.

Boundary Layer Thickness (δ): It is the distance from the boundary to the point where velocity of fluid is approximately equal to 99% of free stream velocity. It is represented by δ.

Displacement Thickness (δ*): It is observed that inside the boundary layer velocity of fluid is less than free stream velocity hence, discharge is less in this region. To compensate for reduction in discharge the boundary is displaced outward in perpendicular direction by some distance. This distance is called displacement thickness (δ*).

Momentum Thickness (θ): As due to boundary layer reduction in velocity occurs so, momentum also decreases. Momentum thickness is defined as the distance measured normal to boundary of solid body by which the boundary should be displaced to compensate for the reduction in momentum of flowing fluid.

![]()

Energy Thickness (δ**): It is defined as distance measured perpendicular to the boundary of solid body by which the boundary should be displaced to compensate for reduction in kinetic energy of flowing fluid (KE decreases due to formation of boundary layer)

Boundary Conditions for the Velocity Profile: Boundary conditions are as

![]()

![]()

Laminar Flow: A flow in which fluid flows in layer and no intermixing with each other is known as laminar flow. For circular pipe, flow will be laminar.

![]()

Where, ρ = Density of fluid, v = Velocity of fluid,

D = Diameter of pipe, μ = Viscosity of fluid.

For flat plate flow will be laminar.

![]()

Where L is length of plate.

Turbulent Flow:

In this flow, adjacent layer of fluid cross each other (particles of fluid move randomly instead of moving in stream line path), for flow inside pipe. If Re > 4000, the flow is considered turbulent, for flat plate, Re > 5 × 105.

Von Karman Momentum Integral Equation

![]()

where, θ = momentum thickness

Shear stress:

Where, U = Free stream velocity; ρ = Density of fluid.

Local Coefficient of Drag (CD*):

It is defined as the ratio of the shear stress τ0 to the quantity ![]()

It is denoted by

Average Coefficient of Drag (CD):

It is defined as the ratio of the total drag force to ![]()

Where, A = Area of surface,

U = Free stream velocity, ρ = Mass density of fluid.

Blassius Experiment Results

For laminar flow,

Coefficient of drag

Average coefficient of drag

For turbulent flow,

where x = Distance from leading edge, Rex = Reynolds's number for length x.

ReL = Reynolds's number at end of plate

Coefficient of drag

Average coefficient of drag

For laminar flow

![]()

f = Boundary layer thickness,

![]()

τ0 = Shear stress at solid surface

x = Distance from where solid surface starts.

Velocity profile for turbulent boundary layer is

Conditions for Boundary Layer Separation: Let us take curve surface ABCSD where fluid flow separation print S is determined from the condition  .

.

If

the flow is separated ![]()

If

the flow is on the average of separation

![]()

If  the flow will not separate or flow will remain attained

the flow will not separate or flow will remain attained ![]()

Methods of Preventing Separation of Boundary Layer: Suction of slow-moving fluid by a suction slot.

- Supplying additional energy from a blower.

- Providing a bypass in the slotted

- Rotating boundary in the direction of flow.

- Providing small divergence in a diffuser.

- Providing guide blades in a bend.

- Providing a trip wire ring in the laminar region for the flow over a sphere.

Comments

write a comment