Time Left - 25:00 mins

ESE ME Machine Design : National Champion Test

Attempt now to get your rank among 338 students!

Question 1

Average value of effective coefficient of friction for bearings are described below:

1). Spherical ball bearing

2). Cylindrical roller bearing

3). Taper roller bearing

4). Stable (thick film) sliding

Contact bearing

Which one of the following sequences is correct?

1). Spherical ball bearing

2). Cylindrical roller bearing

3). Taper roller bearing

4). Stable (thick film) sliding

Contact bearing

Which one of the following sequences is correct?

Question 2

Match List-I (type of gear failure) with List-II (Reasons) select the correct answer using the code given below the lists:

List-I

A). Scoring

B). Pitting

C). Scuffing

D). Plastic flow

List-II

1). Oil film breakage

2). Yielding of surface under heavy loads

3). Cyclic loads causing high surfaces stress

4). Insufficient lubrication

List-I

A). Scoring

B). Pitting

C). Scuffing

D). Plastic flow

List-II

1). Oil film breakage

2). Yielding of surface under heavy loads

3). Cyclic loads causing high surfaces stress

4). Insufficient lubrication

Question 3

A square key of side d/4 is to be fitted on a shaft of diameter d and in the hub of a pulley. If the material of the key and shaft is same and the two are to be equally strong in shear, what is the length of the key?

Question 4

In a particular application, the shaft is subjected to bending loads and also large axial loads. The bearing suitable for supporting such a shaft is

Question 5

Assertion (A): In steady state rotating condition the journal inside a hydrodynamic journal bearing remains floating on the oil film.

Reason (R):The hydrodynamic pressure developed in steady rotating conditions in journal bearings balances the load on the journal.

Reason (R):The hydrodynamic pressure developed in steady rotating conditions in journal bearings balances the load on the journal.

Question 6

In journal bearing design, the factor  is called the ‘Bearing characteristic number’ where Z= absolute viscosity of the lubricant, N=speed of journal in rpm and P= bearing pressure on the projected bearing area. The value of

is called the ‘Bearing characteristic number’ where Z= absolute viscosity of the lubricant, N=speed of journal in rpm and P= bearing pressure on the projected bearing area. The value of  corresponding to the minimum amount of friction is called the bearing modulus ‘K’. For hydrodynamic lubrication of the bearing,

corresponding to the minimum amount of friction is called the bearing modulus ‘K’. For hydrodynamic lubrication of the bearing,  should be

should be

Question 7

Satisfactory hydrodynamic film in a journal bearing is formed when

Question 8

Match List-I (Type of Anti-friction Bearing) with List-II (Specific Use) select the correct answer using the code given below the lists:

List-I

A). Self-aligning ball bearing

B). Taper roller bearing

C). Deep groove ball bearing

D). Thrust ball bearing

List-II

1). For pure axial load

2). For hinged condition

3). For pure radial load

4). For axial and radial load

List-I

A). Self-aligning ball bearing

B). Taper roller bearing

C). Deep groove ball bearing

D). Thrust ball bearing

List-II

1). For pure axial load

2). For hinged condition

3). For pure radial load

4). For axial and radial load

Question 9

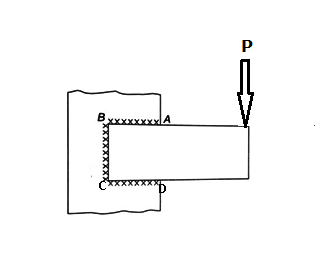

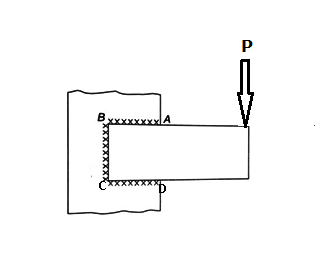

two plates are jointed as shown in the figure

The maximum tensile and shear stresses are and

and  respectively. The plate is 70 mm wide and 12.5 mm thick. What will be value of

respectively. The plate is 70 mm wide and 12.5 mm thick. What will be value of  if the total load carried by the joint is 85 kN?

if the total load carried by the joint is 85 kN?

The maximum tensile and shear stresses are

Question 10

Assertion (A): In design of double welds in fillet unsymmetrical sections with plates subjected to axial loads lengths of parallel welds are made unequal.

Reason (R): The lengths of parallel welds in fillet welding of an unsymmetrical section with a plate are so proportioned that the sum of the resisting moments of welds about the Centre of gravity axis is zero.

Reason (R): The lengths of parallel welds in fillet welding of an unsymmetrical section with a plate are so proportioned that the sum of the resisting moments of welds about the Centre of gravity axis is zero.

Question 11

Consider the following:

The parallel fillet welded joint is designed for

1). Tensile strength

2). Compressive strength

3). Bending strength

4). Shear strength

Which of the above is/are correct?

The parallel fillet welded joint is designed for

1). Tensile strength

2). Compressive strength

3). Bending strength

4). Shear strength

Which of the above is/are correct?

Question 12

A compound fillet welded joint is loaded by P as shown. The maximum shearing stress occurs at point

Question 13

Assertion (A): In design of friction clutches the torque transmission capacity id predicted from the condition of uniform rate of wear of friction plate.

Reason (R):With the use of hard materials for the friction lining there is always perfect geometrical fit between two surfaces and hence pressure distribution over the contact zone is not uniform.

Reason (R):With the use of hard materials for the friction lining there is always perfect geometrical fit between two surfaces and hence pressure distribution over the contact zone is not uniform.

Question 14

Assertion A. : Centrifugal clutches are designed to provide automatic and smooth engagement of load to driving member.

Reason (R):Since the operating centrifugal force is a function of square of angular velocity, the friction torque accelerating a load is also a function of square of speed of driving member.

Reason (R):Since the operating centrifugal force is a function of square of angular velocity, the friction torque accelerating a load is also a function of square of speed of driving member.

Question 15

Assertion (A): The Lewis equation for design of gear tooth predicts the static load capacity of a cantilever beam of uniform strength.

Reason (R):According to law of gears interchangeability is possible only when gears have same pressure angle and same module.

Reason (R):According to law of gears interchangeability is possible only when gears have same pressure angle and same module.

Question 16

Consider the following statements pertaining to the basic Lewis equation for the strength design of spur gear teeth

1). Single pair of teeth participates in power transmission ay any instant.

2). The tooth is considered as a cantilever beam of uniform strength.

3). Loading on the teeth is static in natural

4). Lewis equation takes into account the inaccuracies of the tooth profile

5). Meshing teeth come in contact suddenly.

Which of these statements are correct?

1). Single pair of teeth participates in power transmission ay any instant.

2). The tooth is considered as a cantilever beam of uniform strength.

3). Loading on the teeth is static in natural

4). Lewis equation takes into account the inaccuracies of the tooth profile

5). Meshing teeth come in contact suddenly.

Which of these statements are correct?

Question 17

A spur gear transmits 10 kW at a pitch line velocity of 10 m/s; driving gear has a diameter of 1.0m. find the tangential force between the driver and the follower, and the transmitted torque respectively.

Question 18

A 1.5 kW motor is running at 1440 rev/min. It is to be connected to a stirrer running at 36 rev/min. The gearing arrangement suitable for this application is

Question 19

A force ‘F’ is to be transmitted through a square-threaded power screw into a nut. If ‘t’ is the height of the nut and ‘d’ is the minor diameter, the which one of the following is the average shear stress over the screw thread?

Question 20

Power screws are used to produce uniform, slow and powerful motion such as required in presses, jacks and other machinery. ’V’ threads are usually not used for this application due to low efficiency. This is because:

Question 21

The efficiency of a power screw is maximum, when the lead (helix) angle is

Question 22

Two concentric springs, having same number of turns and free axial length, are made of same material. One spring has mean coil diameter of 12 cm and its wire diameter is 1.0 cm, the other one has ,mean coil diameter of 8 cm and wire diameter of 0.6 cm. If the set of springs is compressed by an axial load of 2000 N, the loads shared by the springs will be

Question 23

If both the mean coil diameter and wire diameter of a helical compression or tension spring be double, then the deflection of the spring close coiled under same applied load will

Question 24

Disruptive strength is the maximum strength of a metal, when

Question 25

Assertion (A): The Lewis equation for design of involute gear tooth predicts the static load capacity of a cantilever beam of uniform strength.

Reason (R):For a pair of gears in mesh, pressure angle and module must be same to satisfy the condition of interchange ability and correct gearing.

Reason (R):For a pair of gears in mesh, pressure angle and module must be same to satisfy the condition of interchange ability and correct gearing.

- 338 attempts

- 1 upvote

- 11 comments

Dec 7ESE & GATE ME