- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Testing of Materials with Universal Testing Machine

By BYJU'S Exam Prep

Updated on: September 25th, 2023

A Universal Testing Machine (UTM) is a mechanical testing instrument. Testing of Materials is a very important part of Material Testing from the point of view of design and manufacturing. It provides information on material properties, helps ensure quality, helps prevent failures, and helps make choices among different available materials. Testing of Materials with Universal Testing Machine article gives you deep insight into the concepts related to testing materials with UTM.

Universal Testing Machine PDF(Download Notes)

UTMs are used in a wide range of industries, including aerospace, automotive, construction, and manufacturing. Testing of Materials with a Universal Testing Machine is a part of the Strength of Materials subject that covers good weightage of the questions for GATE, SSC JE, ISRO, ESE, and other mechanical engineering exams. Let’s deep dive into the concepts related to Testing Materials with a Universal Testing Machine.

Download Formulas/short Notes for GATE Mechanical Engineering – TOM & Vibrations PDF

Table of content

Testing of Materials with a Universal Testing Machine

Testing of Materials with a Universal Testing Machine is a very important part of the from the point of view of design and manufacturing. Testing of Materials with a Universal Testing Machine provides information on material properties to prevent failures and helps make choices among different available materials.

During a typical test, the specimen is placed in the grips or fixtures, and a load is applied to the specimen at a constant rate until it either breaks or reaches a specified deformation. There are mainly two types of testing performed on materials: Mechanical testing and Non-destructive testing. Here, only mechanical testing will be discussed.

Mechanical Testing

Mechanical testing is a destructive type of testing that utilizes static or dynamic forces to reveal the material’s properties. Mechanical testing includes different types of testing such as Tensile test, hardness testing, impact test, fatigue test, creep test, bend test, etc.

Tensile Testing on Universal Testing Machine

This test is performed on universal testing machines (UTM). In this test, the specimen is subjected to uniaxial tensile force in a controlled way until its failure. This test helps us access the following properties ductility, yield strength, tensile strength, Young’s modulus (E), and Poisson’s ratio (μ).

Select the standard specimen and grip it in the crossheads with proper adjustment. While setting up the job, use the adjusting knob to make zero at lower points zero to remove the dead weight of the lower table. Now, lock the job, fix the extensometer between the gauge length ( to find the extension), and apply the

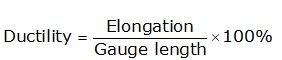

Ductility: It relates to the elongation during the tensile test of the material, and it is defined as the percentage elongation.

Tensile strength

It is defined as the maximum load per unit cross-section area the material can bear before breaking. It is given as follows:

![]()

Yield Strength

It is the strength of the material above which permanent deformation takes place in the material under stress.

It is also known as the material’s modulus of elasticity (E), and it represents the material’s stiffness. It is the measure of the regain of shape and size of the material on the removal of the load.

Compression Test by Universal Testing Machine

A compression test is also carried out on the universal testing machine (UTM). Here, the load applied is compressive, and the specimen is loaded until it fails. The compression test is generally carried out for Brittle materials.

Hardness Test

Hardness is the material’s surface property, which shows a material’s resistance against indentation, penetration, and scratching. Hardness tests are as follows:

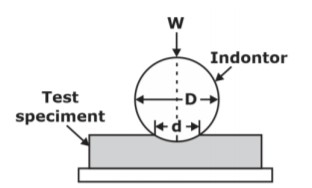

Brinell Hardness Test

In the Brinell hardness test, a steel or tungsten carbide ball is used to make an impression in the material under a specified load.

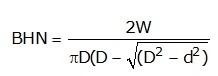

Vickers Hardness Test

It uses the pyramid indenter of a square shape, and the length of the diagonals of the indentation is measured to calculate the hardness number. It is suitable for very hard and tough materials.

Vickers hardness number is given by:

VHN 1.854 (F/D2)

Where F is the applied force (in kg) and D is the average diameter of the diagonals measured.

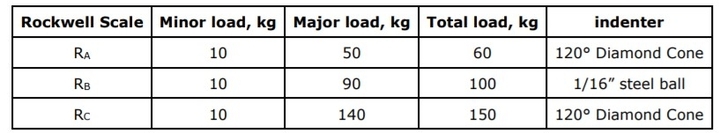

Rockwell Hardness Test

Rockwell test sues the diamond cone-shaped or spherical ball type of indenter for the indentation purpose. There are many scales in the Rockwell testing, but the C scale is the most commonly used, and its hardness is denoted as HRC.

Toughness or Impact test

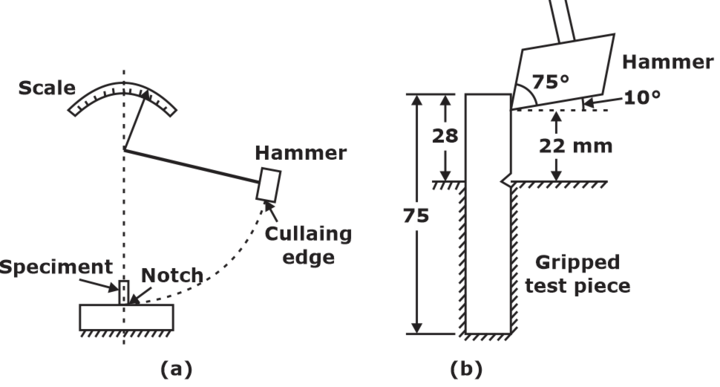

Toughness tests are carried out at high strain rates, and the energy absorbed by the materials in breaking the specimen is considered the toughness of the material. There are two types of impact tests named Izod and Charpy tests.

Izod Test

For Izod impact testing, the specimen is kept vertically as a cantilever beam. The specimen is kept so that the notched side faces the striking hammer.

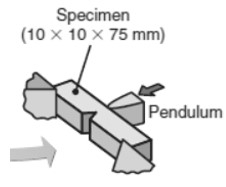

Charpy Test

The Charpy test shows whether a metal is either brittle or ductile and is used to predict ductile to brittle transition. In the Charpy test, the specimen is placed horizontally and fixed at both ends i.e. it is a simply supported beam. Striking hammer strikes from the opposite side of the notch.

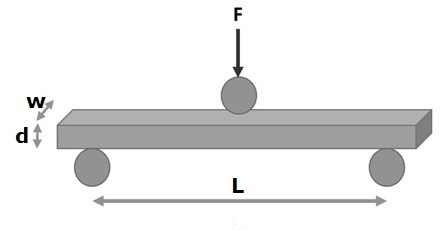

Flexural or Bending Test

The bend test is a qualitative test that can be used to assess a workpiece’s ductility and soundness. Generally, it is used for the butt-welded joints to control their quality. In bend tests, the Rectangular specimen is supported at both ends, and the load is applied vertically at one or two points. The fracture stress in bending is called the modulus of rupture, flexural strength.

Shear Test

The shear test is used to determine the material’s shear strength, which is the maximum shear stress that the material can bear before the appearance of any failure. It plays a key role in the design of fasteners such as bolts and screws.

Fatigue Test

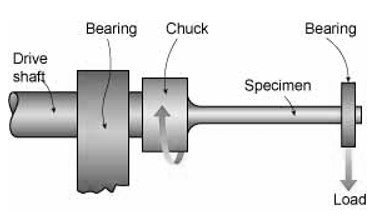

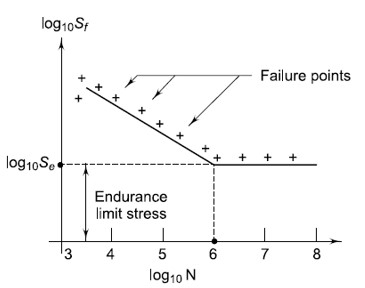

Fatigue is the permanent failure of the material due to fluctuating stresses, and failure takes place below the yield point of the metal. The number of cycles at which failure occurs is measured; these can vary from a couple of hundred to millions of cycles.

The failure of the specimen under rotating loading is termed fatigue failure. Rotating loading results in completely reversed stresses.

The fatigue test results are plotted as an S–N curve, which is the graphical representation of stress amplitude and the number of stress cycles (N) before the fatigue failure on a log-log graph paper.

Get complete information about the GATE exam pattern, cut-off, and all those related things on the BYJU’S Exam Prep official youtube channel.