- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

What are Theories of Failure?

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Theories of Failure is a set of theories especially designed for complex stress systems such as 3-D stresses. Whenever an engineer designs a machine or any mechanical components, the main objective is that it should not fail under its operating or working condition. This is the biggest challenge for the engineer, and this is one of the main reasons to introduce the concept of theories of failure. So, depending upon the working condition and the properties of the used material, engineers use different theories of failure.

When we apply force/Load on the material, stress will be produced in the material, which leads to cause strain; depending on the stress-strain behaviour of a specific loading, several theories of failure have been introduced.

Download Formulas for GATE Mechanical Engineering – Machine Design

Table of content

-

1.

What are the Theories of Failure?

-

2.

Types of Theories of Failure

-

3.

Maximum Principal Stress Theory or Rankine’s Theory

-

4.

Maximum Principal Strain Theory or St. Venant’s Theory

-

5.

Maximum Shear Stress Theory or Guest and Tresca’s Theory

-

6.

Maximum Strain Energy Theory or Haigh’s Theory

-

7.

Maximum Shear Strain Energy Theory or Von-Mises and Henckey Theory

What are the Theories of Failure?

Various load types or combinations act over the components while under operating conditions. So, the theories of failure help to give a safe dimension to machine components. Before learning about Theories of Failure, let us briefly learn about a machine’s failure.

Failure of Machine

The meaning failure of the machine is the non-ability of the component or a machine to perform its function as per requirement. Failure of a machine or any mechanical components does not mean a total breakdown or not operating. It can operate but not as per our requirements.

Download Formulas for GATE Mechanical Engineering – Strength of Materials

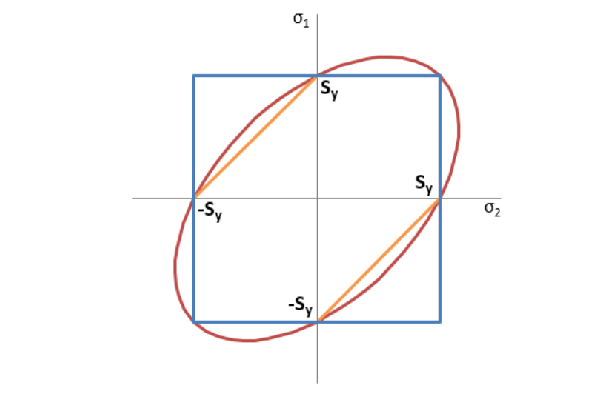

Theories of Failure Diagram

The diagram shown below shows a graphical representation of various Theories of Failure for ductile material:

For example, A mechanical shaft transmits the power, but due to increased load, it gets bent slightly. Still, it can transmit power but not that efficiently. In this case, we can say that failure of the shaft happens.

The factor of Safety (FOS)

- The ratio of ultimate to allowable load or stress is known as a factor of safety, i.e., the ratio of the material strength or failure stress to the allowable or working stress.

- The factor of safety must always be greater than unity. It is easier to refer to the ratio of stresses since this applies to material properties.

FOS = Failure Stress/Working or Allowable Stress

Download Formulas for GATE Mechanical Engineering – TOM & Vibrations

Types of Theories of Failure

Based on the loading condition (Tensile load, compressive load, and shear load) and material behavior (Ductile, plastic, and brittle), there are five main theories of failure:

- Maximum principal stress theory or Rankine’s Theory

- Maximum principal strain theory or St. Venant’s Theory

- Maximum Shear Stress Theory or Guest and Tresca’s Theory

- Maximum Strain Energy Theory or Haigh’s Theory

- Maximum Shear Strain Energy theory or Von-Mises and Henckey Theory

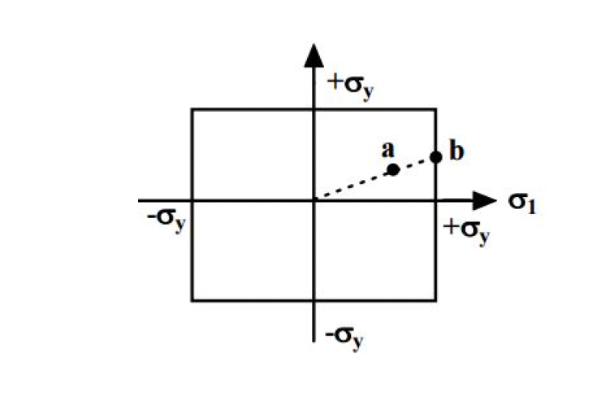

Maximum Principal Stress Theory or Rankine’s Theory

In this case of complex loading, when the maximum principal stress value reaches the ultimate stress or yield stress of the material, the component will get failed.

As brittle material is weak in tension, this is most suitable for the brittle material

In simple tension, σ1= σyt

In compression, σ2= σyc

Where,

- σyt– Ultimate tensile stress

- σyc – Ultimate compressive stress

- σ1– Maximum principal stress

Maximum Principal Strain Theory or St. Venant’s Theory

According to this failure theory, components are safe if the maximum principal strain at a critical point in the loaded member will not exceed the strain under the yielding condition when subjected to uniaxial loading.

It is the most suitable for all types of material, like ductile material, brittle material, and material under hydrostatic conditions.

ε1≤σyt/E

σ1−[ μ ( σ2+ σ3)]≤σyt/E

Where,

- σyt– Ultimate tensile stress

- μ– Poisson ratio

- σ1, σ2, and σ3– Stresses along the x, y, and z-axis

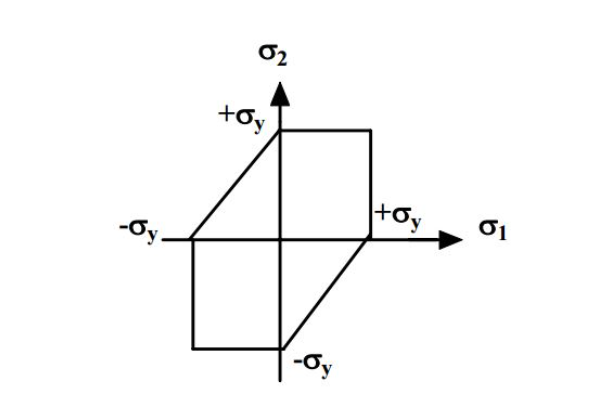

Maximum Shear Stress Theory or Guest and Tresca’s Theory

According to this theory, the material will be failed in the complex loading system at any place in components, and the magnitude of shear stress induced in the material is greater than or equal to the maximum shear stress of the material. Therefore, it is the most suitable theory of failure to experiment on ductile material, especially in the case of a shaft subjected to torque.

The limitation of maximum shear stress theory is that it will not give proper results for a pure shear loading as well as triaxial tensile or compressive loading having approximately equal magnitude (for example body submerge in water)

Maximum Strain Energy Theory or Haigh’s Theory

Per the maximum strain energy theory, failure occurs when the total strain energy in the fundamental component exceeds strain energy under yield conditions. According to this theory, strain can be fully recoverable up to the elastic limit. However, this theory will not give results in the case of triaxial loading having almost equal magnitude.

The Strain energy is developed and stored in the material after the elastic deformation. This energy will also be the work done during the elastic transformation. This theory says the developed strain energy will be responsible for the failure of the strain energy under yield conditions.

Maximum Shear Strain Energy Theory or Von-Mises and Henckey Theory

It is also known as the maximum distortion energy theory. As it was introduced by the scientists Von-Mises and Hickey, it is also known as von Mises-Hencky’s theory. When loads are applied to the component, it will deform, due to which the size and shape of the components will change. The energy responsible for changes in shape and volume is known as distortion energy.

Maximum shear strain theory state that distortion energy associated with the unit volume of the member exceeds the distortion energy at uniaxial loading per unit volume.