- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Pressure Measurement

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Pressure Measurement is a method of measuring pressure in a confined space. Before we go into the specifics of what pressure measurement is, let’s define pressure. The perpendicular force per unit area, or the tension at a point within a confined fluid, is known as the pressure in the physical sciences. The force exerted on a floor by a 42-pound box with an area of 84 square inches at the bottom is equal to the force divided by the area over which it is exerted, or half-pound per square inch. Atmospheric pressure is the weight of the atmosphere pressing down on each unit area of the Earth’s surface, which is around 15 pounds per square inch at sea level.

Pressure is measured in pascals in SI units, with one pascal equaling one newton per square meter. The pressure in the atmosphere is close to 100,000 pascals. Let’s go through the fundamentals of pressure and pressure measurement, as well as the many types of pressure and pressure gauges.

Table of content

Introduction to Pressure Measurement

Pressure is defined as the force per area that a liquid, gas, or vapor, can exert on a particular surface. Absolute, gauge, or differential pressure can be used to measure the applied pressure. Pressure can be measured directly by measuring the applied force or indirectly by measuring gas properties, for example. Thermal conductivity and ionization of gas molecules are examples of indirect pressure measurement techniques that use gas properties.

Prior to the invention of mechanical manometers and electronic diaphragm pressure sensors, pressure measurement was done using mercury or water-based liquid manometers. Ordinary gauges on Earth, such as a tire-pressure gauge, measure pressures that are higher than air pressure. As an example, the gauge pressure on a tyre gauge could be 30 pounds per square inch. The air within the tyre exerts 45 pounds per square inch of absolute pressure, including ambient pressure. Negative gauge pressures, which correspond to partial vacuums, are lower than atmospheric pressures.

Basics of Pressure Measurement

One of the most important variables in engineering is pressure and pressure measurement. Pressure is a scalar quantity. It connects the normal force operating on the surface to the vector area element (a vector normal to the surface).

Pressure Measurement Unit

The SI unit for Pressure measurement is Pascal (Pa).

The scalar proportionality constant that connects the two normal vectors is called pressure. To understand pressure measurement, one must first understand the many types of pressure. There are five different types of pressure:

- Atmospheric Pressure

- Vacuum Pressure

- Gauge Pressure

- Absolute Pressure

- Differential Pressure

Atmospheric Pressure

Atmospheric pressure, often known as barometric pressure, is the force exerted by an atmospheric column per unit area (that is, the entire body of air above the specified area). A mercury barometer (thus the often used synonym for barometric pressure) can be used to measure atmospheric pressure since it indicates the height of a mercury column that perfectly balances the weight of the atmosphere column above the barometer.

Vacuum Pressure

A vacuum is a space that is completely devoid of matter. The word comes from the Latin adjective vacuus, which means void or empty. A zone with a gaseous pressure significantly lower than atmospheric pressure is an approximation to such a vacuum.

Gauge Pressure

The pressure measured against the ambient air pressure is known as gauge pressure. A diaphragm sensor can be used to measure gauge pressure, with one side of the diaphragm exposed to the pressure media to be measured and the other side exposed to ambient atmospheric pressure.

Absolute Pressure

Absolute pressure is defined as any pressure detected above the absolute zero of pressure. It is equal to measuring pressure + ambient pressure and is measured with a barometer.

Differential Pressure

Differential pressure is the difference between the pressures sensed by the high-pressure and low-pressure ends of the differential pressure transmitter. It is commonly used to measure the flow of gas or liquid.

Pressure Measurement Standards

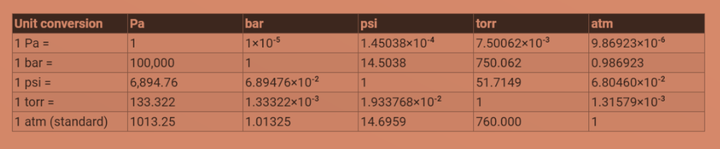

The are various standards assigned for Pressure Measurement. The SI unit for measuring pressure is the pascal, and the sign for pressure in physical science is p. (symbol: Pa). A pascal is one Newton per square meter of force exerted perpendicularly on a surface. Psi (pounds per square inch), torr, and bar are other regularly used pressure units for expressing pressure levels.

Pressure Measurement units are used differently depending on geography and application: in the United States, psi is usually employed, whilst in Europe, the bar is the favored unit of measurement. Torr is the favored pressure unit in the industrial vacuum community in the United States, mbar in Europe, and pascal in Asia.

Pressure Measurement Devices

The Pressure measurement within the system is often crucial to know depending on the application. It provides proper operation, uniform product, and protection against over-pressurized vessels. Pressure measurement gauges are used to determine how much pressure is present in a system. Pressure gauges are most commonly used to measure gauge pressure, which indicates the pressure within a system in relation to atmospheric pressure.

The pressure gauge measures this in a variety of ways, depending on its design. The pressure measurement devices are as follows:

- Bourdon Tube Pressure Gauge

- Diaphragm Pressure Gauge

- Capsule Pressure Gauge

- Absolute Pressure Gauge

- Differential Pressure Gauge

- Bellows Pressure Gauge

- Piezometer Pressure Gauge