- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

I.C. Engines: Meaning and Working

By BYJU'S Exam Prep

Updated on: September 25th, 2023

An IC engine is a type of heat engine that converts fuel into useful work through a series of controlled explosions. The internal combustion engine operates by the combustion of fuel within a confined space, such as a cylinder, which pushes a piston, creating motion. This motion is then transformed into rotary motion by a crankshaft, which can be used to power a wide range of machines and vehicles, including automobiles, motorcycles, generators, and aircraft.

IC Engine PDF(Download Now)

IC engines have been a staple of the transportation and energy industries for over a century and continue to play a major role in powering the modern world. They are widely used due to their high power-to-weight ratio, ease of use, and adaptability to a range of fuels, including gasoline, diesel, and natural gas. IC engines have undergone significant technological advancements over the years, improving their efficiency, reducing emissions, and increasing their power output. Despite the advent of electric vehicles and alternative energy sources, the IC engine remains a critical component of the global energy landscape, and its future is likely to be shaped by the ongoing quest for clean and sustainable energy solutions.

Download Formulas for GATE Mechanical Engineering – TOM & Vibrations

Table of content

-

1.

What is an IC Engine?

-

2.

Working of IC Engine

-

3.

Classification of IC Engine

-

4.

Classification of IC Engine Based on Cycle Type

-

5.

Classification of IC Engine Based on Fuel Type

-

6.

Classification of IC Engine Based on Engine Configuration

-

7.

Classification of IC Engine Based on Number of Strokes

-

8.

Basic Engine Components

-

9.

Nomenclature of IC Engine

-

10.

Applications of IC Engine

-

11.

Advantages of IC Engines

-

12.

Disadvantages of IC Engine

What is an IC Engine?

An IC Engine is a machine that transforms the energy released from the combustion of fuel into mechanical energy. The motion of the piston is then converted into rotary motion by a crankshaft, which can be used to drive a wide range of machines and vehicles. IC engines come in different types, including reciprocating engines, such as spark ignition engines and diesel engines, and rotary engines, such as the Wankel engine.

Formulas for GATE Mechanical Engineering – Manufacturing Engineering and Materials

IC Engine Full Form

The full form of IC engine is Internal Combustion engine. The combustion of fuel occurs inside the engine’s cylinders, where a mixture of fuel and air is ignited, creating high-pressure gases that push a piston.

They are widely used due to their high power-to-weight ratio, ease of use, and adaptability to a range of fuels, including gasoline, diesel, and natural gas. Over the years, IC engines have undergone significant technological advancements, improving their efficiency, reducing emissions, and increasing their power output. Despite the advent of electric vehicles and alternative energy sources, the IC engine remains a critical component of the global energy landscape. Its future will likely be shaped by the ongoing quest for clean and sustainable energy solutions, as well as advances in technology that allow for improved performance and efficiency.

Working of IC Engine

An IC (Internal Combustion) engine is a heat engine that converts chemical energy stored in the fuel into mechanical energy. It is used in vehicles, generators, and various other applications. The working of an IC engine can be explained in the following steps:

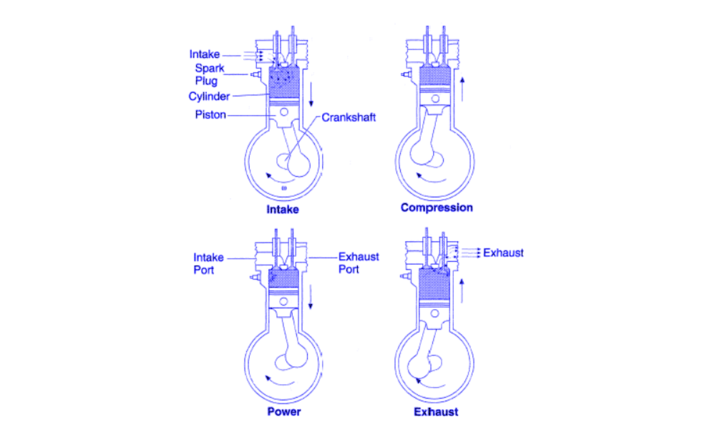

Intake stroke

The first stroke is called the intake stroke. In this stroke, the fuel-air mixture is drawn into the engine cylinder through the open intake valve.

Compression stroke

The second stroke is called the compression stroke. In this stroke, the piston compresses the fuel-air mixture inside the cylinder by moving upwards.

Power stroke

The third stroke is called the power stroke. In this stroke, the fuel-air mixture is ignited by a spark plug or a high-pressure injector, causing an explosion that forces the piston to move downward. This downward motion of the piston is the source of mechanical energy.

Formulas for GATE Mechanical Engineering – Strength of Materials

Exhaust stroke

The fourth and final stroke is called the exhaust stroke. In this stroke, the exhaust valve opens, and the piston moves upward, pushing the exhaust gases out of the engine through the open exhaust valve.

The above four strokes collectively form a cycle known as the four-stroke cycle, which is used in most modern IC engines. Some engines, however, use a two-stroke cycle, which involves only two strokes, i.e., the compression stroke and the power stroke. In a two-stroke cycle, the fuel-air mixture is drawn into the engine cylinder and ignited every other stroke.

Classification of IC Engine

IC engines can be classified based on several parameters, such as the method of ignition, the number of strokes, the type of fuel used, the arrangement of cylinders, and many more. Each classification has its own set of advantages and disadvantages, and it is crucial to choose the appropriate type of IC engine for a specific application to optimize its performance and efficiency. In this article, we will explore the different types of IC engines based on various parameters and their characteristics.

Classification of IC Engine Based on Cycle Type

IC (Internal Combustion) engines are classified based on the type of cycle they follow. There are two main types of cycles: the Otto cycle and the Diesel cycle. Engines that follow the Otto cycle are called petrol engines, while those that follow the Diesel cycle are called diesel engines. Another cycle, known as the dual cycle, is a combination of the Otto and Diesel cycles and is used in some engines.

Four-Stroke Cycle Engine

In a four-stroke cycle engine, the piston completes four strokes (two upstrokes and two downstrokes) to complete one cycle. The four strokes are named intake, compression, power, and exhaust stroke. In the intake stroke, the fuel-air mixture is drawn into the cylinder. The piston then moves upward to compress the mixture in the compression stroke. The spark plug ignites the compressed fuel-air mixture in the power stroke, causing a rapid expansion of gases that pushes the piston down. Finally, in the exhaust stroke, burnt gases are expelled from the engine.

Two-Stroke Cycle Engine

In a two-stroke cycle engine, the piston completes two strokes (one upstroke and one downstroke) to complete one cycle. The two strokes are named compression and power stroke. The fuel-air mixture is drawn into the crankcase in the compression stroke. As the piston moves upward, it compresses the fuel-air mixture in the crankcase. When the mixture is compressed, it is forced upwards into the cylinder through the transfer port. The spark plug ignites the mixture, causing a rapid expansion of gases that pushes the piston down. Finally, in the exhaust stroke, burnt gases are expelled from the engine.

Classification of IC Engine Based on Fuel Type

IC engines can be classified based on the type of fuel used in them. The fuel type plays a significant role in determining the engine’s performance, efficiency, emissions, and operational cost. Broadly, IC engines can be classified into two categories based on the type of fuel used: spark-ignition engines (SI engines) and compression-ignition engines (CI engines).

Spark-Ignition Engines (SI Engines)

SI engines, also known as gasoline engines, use gasoline as their primary fuel. The combustion process in SI engines is initiated by an electric spark, which ignites the fuel-air mixture in the cylinder. SI engines are commonly used in passenger cars, motorcycles, and small aircraft. These engines are known for their high power output, smooth operation, and relatively low emissions.

Compression-Ignition Engines (CI Engines)

CI engines, also known as diesel engines, use diesel as their primary fuel. The combustion process in CI engines is initiated by the high temperature and pressure of the compressed air in the cylinder, without the need for an external ignition source. CI engines are commonly used in heavy-duty vehicles, such as trucks, buses, and construction equipment, as well as in marine and stationary power applications. These engines are known for their high fuel efficiency, low operational cost, and durability.

Classification of IC Engine Based on Engine Configuration

Internal combustion engines (IC engines) can be classified based on their engine configuration into two categories: reciprocating engines and rotary engines. Reciprocating engines include the commonly used four-stroke and two-stroke engines, while rotary engines include Wankel and turbine engines. The classification is based on the motion of the engine components that convert the fuel energy into mechanical energy.

Inline Engines

In an inline engine, the cylinders are arranged in a straight line. This configuration is commonly used in small cars and motorcycles.

V-shaped Engines

In a V-shaped engine, the cylinders are arranged in a V-shape. This configuration is commonly used in larger cars and trucks.

Flat or horizontally opposed engines

In a flat engine, the cylinders are arranged in a horizontally opposed configuration, with two banks of cylinders facing each other. This configuration is commonly used in aircraft and some high-performance sports cars.

Radial engines

In a radial engine, the cylinders are arranged in a circular pattern around the crankshaft. This configuration is commonly used in aircraft.

Classification of IC Engine Based on Number of Strokes

IC engines can be classified based on the number of strokes involved in each cycle of the engine. The strokes refer to the movement of the piston in the engine cylinder. There are two main types of IC engines based on the number of strokes:

Two-Stroke Engine

A two-stroke engine completes one power cycle in two strokes of the piston, i.e. one upstroke and one downstroke. The upstroke compresses the air-fuel mixture in the cylinder, while the downstroke produces power by combusting the compressed mixture. These engines are simpler and lighter than four-stroke engines, but they are less fuel-efficient and more polluting.

Four-Stroke Engine

A four-stroke engine completes one power cycle in four strokes of the piston, i.e. one upstroke, one downstroke, and two strokes in between. These two intermediate strokes are the intake stroke and the exhaust stroke. In the intake stroke, the air-fuel mixture is drawn into the cylinder, while in the exhaust stroke, the burned gases are expelled out of the cylinder. Four-stroke engines are more fuel-efficient and less polluting than two-stroke engines, but they are more complex and heavier.

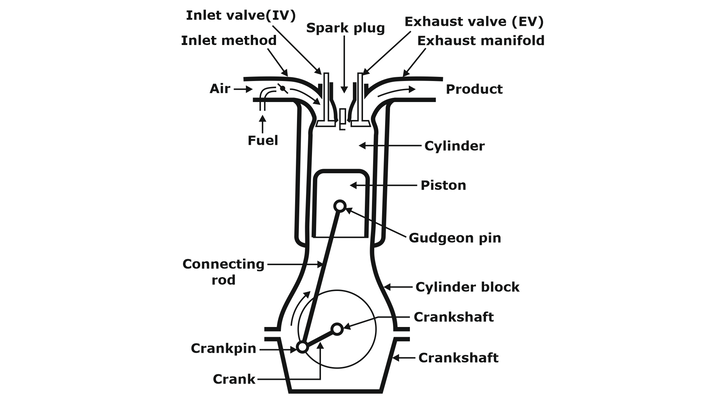

Basic Engine Components

The basic components of an engine include the cylinder block, cylinder head, piston, connecting rod, and crankshaft. The cylinder block houses the cylinders and forms the main structure of the engine. The cylinder head covers the top of the cylinders and houses the valves and combustion chamber. The piston moves up and down inside the cylinder, while the connecting rod connects the piston to the crankshaft. The crankshaft converts the reciprocating motion of the piston into rotational motion, which drives the wheels of a vehicle or the blades of a generator.

Nomenclature of IC Engine

The nomenclature of an IC engine refers to the naming system used for its components, such as cylinders, pistons, connecting rods, and crankshafts. It helps in identifying and describing the parts of the engine and their functions.

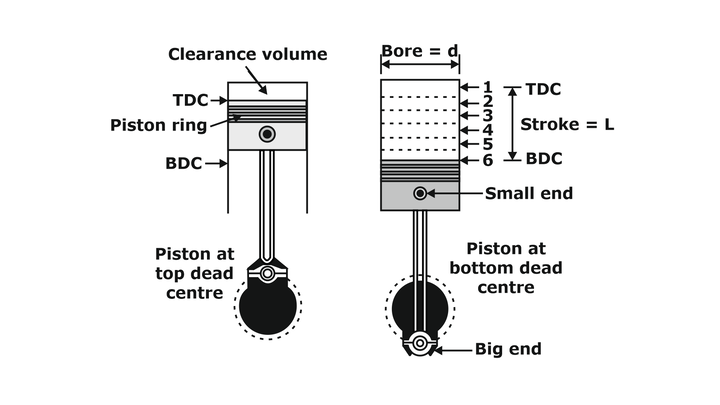

Cylinder Bore (d)

The cylinder bore is the diameter of the cylindrical hole in the engine block where the piston moves up and down to compress the fuel-air mixture and generate power. It determines the displacement of the engine and affects its performance and efficiency.

Piston Area (A)

Piston area (A) refers to the cross-sectional area of the piston in an engine. The piston area plays a crucial role in determining the force generated by the engine during the power stroke.

Stroke (L)

Stroke (L) refers to the distance travelled by the piston from the top dead centre (TDC) to the bottom dead centre (BDC) in a single cycle of operation. It determines the displacement of the engine and affects its power output and efficiency. The stroke is measured in millimetres (mm) or inches (in).

Dead Centre

Dead Centre refers to the position of the piston at the extreme ends of its stroke in an engine. The Top Dead Centre (TDC) is the position when the piston is at the highest point in the cylinder, while the Bottom Dead Centre (BDC) is the position when the piston is at the lowest point in the cylinder. These positions are important for engine timing and ignition purposes.

Displacement or Swept Volume (Vs)

Displacement or Swept Volume (Vs) refers to the total volume of the air-fuel mixture that is displaced by all the pistons in an engine during a single cycle of operation. It is calculated as the product of the cross-sectional area of the piston (A) and the stroke length (L), multiplied by the number of cylinders in the engine. The displacement is expressed in cubic centimeters (cc) or liters (L) and is a crucial parameter that determines the power output and performance of the engine.

Compression Ratio (r)

Compression Ratio (r) refers to the ratio of the volume of the combustion chamber when the piston is at the bottom dead center (BDC) to the volume of the combustion chamber when the piston is at the top dead center (TDC). It is a crucial parameter that determines the efficiency and performance of an engine. A higher compression ratio leads to a more efficient combustion process, which results in increased power output and fuel efficiency. The compression ratio is usually expressed as a decimal or a ratio, such as 10:1. It is the ratio of the total cylinder volume when the piston is at the bottom dead center, VTotal, to the clearance volume, Vc.

r = VTotal/Vc = [Vc+Vs]/Vc = 1 + Vs/Vc

Applications of IC Engine

Internal combustion engines (IC engines) are widely used in transportation, power generation, and industrial equipment. They power cars, trucks, boats, motorcycles, and airplanes, as well as generators, pumps, and compressors. IC engines can run on a variety of fuels including gasoline, diesel, natural gas, and biofuels. IC engines have a wide range of applications in various industries and sectors. Some of the common applications of IC engines are:

-

Automobiles: IC engines are widely used in automobiles such as cars, buses, trucks, and motorcycles to power vehicles.

-

Aircraft: IC engines are also used in small aircraft and helicopters to provide propulsion.

-

Marine: IC engines are used in marine applications such as ships, boats, and submarines.

-

Agriculture: IC engines are used in agriculture for powering farm machinery such as tractors, harvesters, and irrigation pumps.

-

Power generation: IC engines are used for power generation in applications where grid power is unavailable or unreliable, such as remote locations, construction sites, and emergency backup power.

-

Construction: IC engines are used in construction machinery such as excavators, bulldozers, and cranes.

-

Military: IC engines are used in military vehicles, tanks, and aircraft.

-

Small equipment: IC engines are used in a variety of small equipment such as lawnmowers, chainsaws, and generators.

Advantages of IC Engines

Internal combustion engines have the advantages of being powerful, compact, and efficient. They can run on a variety of fuels, including gasoline, diesel, and natural gas. IC engines are also relatively easy to maintain and repair, making them a cost-effective option for transportation and power generation. There are several advantages of internal combustion engines (IC engines) including:

-

High Power Density: IC engines have a high power-to-weight ratio, making them an excellent choice for transportation and power generation applications.

-

Versatile: IC engines can run on a variety of fuels, including gasoline, diesel, natural gas, and biofuels, giving them a wide range of applications.

-

Efficient: Modern IC engines are designed to be highly efficient, with some engines achieving over 50% thermal efficiency.

-

Cost-effective: IC engines are relatively inexpensive to manufacture, and the fuel they use is readily available, making them a cost-effective option for many applications.

-

Durability: IC engines are designed to be rugged and durable, making them ideal for use in harsh environments.

-

Easy to Maintain: IC engines are easy to maintain, with many components easily accessible for inspection and repair.

Overall, the advantages of IC engines make them an important technology for a wide range of applications, from powering vehicles and generators to running pumps and compressors in industrial settings.

Disadvantages of IC Engine

Internal combustion engines (IC engines) have several disadvantages, including producing harmful emissions, requiring fossil fuels, low thermal efficiency, limited lifespan, and high maintenance costs. These engines also generate noise and vibration, contributing to noise pollution and discomfort to passengers.

-

Environmental impact: IC engines release harmful emissions such as carbon dioxide, nitrogen oxides, and particulate matter, contributing to air pollution and climate change.

-

Limited efficiency: IC engines are not very efficient, with only about 20-30% of the fuel’s energy being converted into useful work, with the rest being lost as heat.

-

Noise and vibration: IC engines can be noisy and produce vibrations, which can be uncomfortable for passengers and lead to structural damage.

-

Dependence on fossil fuels: IC engines rely on non-renewable fossil fuels, which are becoming increasingly scarce and expensive.

-

Maintenance requirements: IC engines require regular maintenance and repairs to keep them running smoothly, which can be costly and time-consuming.

-

Safety concerns: IC engines can pose safety risks due to the flammable nature of the fuel and the potential for explosions or fires.

Get complete information about the GATE exam pattern, cut-off, and all those related things on the BYJU’S Exam Prep official youtube channel.