- Home/

- GATE MECHANICAL/

- GATE ME/

- Article

Elasticity: Definition, Formula, and Examples

By BYJU'S Exam Prep

Updated on: September 25th, 2023

Elasticity refers to a body’s ability to resist distorting influences and return to its regular size and shape when that influence or force is removed. When an external force distorts an elastic material, it suffers internal resistance and returns to its original state when the external force is removed. Elastic moduli, such as Young’s, shear, and bulk modulus, are all measures of a material’s inherent elastic qualities as resistance to deformation under an applied load.

Elasticity GATE Notes PDF

When an external force is applied to a rigid body, its length, volume, or shape change; when external influences are eliminated from the body, it returns to its normal shape and size. Elasticity is a feature of a body that allows it to restore its previous form (or) size once external forces are removed. Let’s take deep dive into concepts related to elasticity, along with appropriate examples.

Download Formulas for GATE Mechanical Engineering – Strength of Materials

Table of content

What is Elasticity?

The ability of a body to resist distorting influences and return to its normal size and shape when that influence or force is withdrawn is referred to as elasticity. When sufficient weights are applied to solid objects, they will deform; if the material is elastic, the object will return to its original shape and size following removal. In contrast, plasticity occurs when the thing fails to do so and instead remains distorted. Elasticity is important for the GATE exam. The physical reasons for elastic behaviour might be quite different for different materials.

When forces are applied to metals, the atomic lattice changes size and shape (energy is added to the system). When the forces are released, the lattice returns to its lower energy state. When forces are applied, the stretching of polymer chains creates elastic in rubbers and other polymers.

What is Stress?

When the body is deformed by applying external forces, forces within the body come into play. Internal restorative forces cause elastic bodies to restore their original shape. Internal and external forces act in opposite directions. The stress is defined as the force per unit area when a force F is applied uniformly over a surface of area A.

Stress = Force/Area

S.I unit for stress is Nm2

Types of Stress

Stress is classified into three categories. Types of stress are used for making questions in the GATE question paper. The important types of stress are:

- Longitudinal stress

- Bulk stress or volume stress

- Shear stress or tangential stress

Longitudinal Stress

Longitudinal stress occurs when the stress is normal to the body’s surface area and changes the body’s length. Longitudinal stress and questions based on this concept can be seen in the GATE previous year’s question paper. It is divided into two categories.

- Tensile stress

- Compressive stress.

Tensile Stress

Tensile stress occurs when a substance is under tension. The stretching of the material is caused by forces acting along the axis of force. Tensile stress is the material’s external force per unit area that causes the substance to stretch.

Compressive Stress

Compressive stress is the force responsible for material deformation such that the volume of the material decreases. The stress that a material undergoes causes it to shrink in volume. High compressive stress causes material failure due to tension.

Volume Stress or Bulk Stress

When a deforming force or applied force acts in all dimensions, causing the volume of an object to alter, this is referred to as volumetric stress or bulk stress. Volume stress occurs when a body’s volume changes due to a deforming force.

Tangential Stress

Tangential (or) shear stress occurs when the tension is tangential (or) parallel to the body’s surface. This causes the body’s form to shift or twist.

Download Formulas for GATE Mechanical Engineering – Manufacturing Engineering and Materials

What is a Strain?

When a body is under stress, it deforms. Strain is the fractional change in the dimension of a body caused by external stress acting on it. Strain is defined as the charge-to-original-dimension ratio of any dimension. Strain is only a number because it is the ratio of two similar physical qualities. Strain plays an important role in the GATE ME syllabus. It lacks both a unit and a dimension.

Strains are further categorized into three categories.

- Longitudinal strain

- Volume strain

- Shearing strain or tangential strain

Longitudinal Strain

When stress (external force per unit area) is applied to the body, the deforming force alone causes a change in length, and the body surpasses its elastic limit. The longitudinal strain refers to the state or strain caused in the body.

Volume Strain

Volumetric strain is the ratio of a body’s change in volume to its initial volume caused by external deformation-producing forces. Dilation is another name for it. The symbol EV commonly represents the volumetric strain, and the general equation for volumetric strain is given as –

EV=ΔV/V

Shearing Strain

This strain occurs when the deforming force changes the body’s shape. It is defined as a layer’s displacement ratio to its distance from a fixed layer.

Download Formulas for GATE Mechanical Engineering – TOM & Vibrations

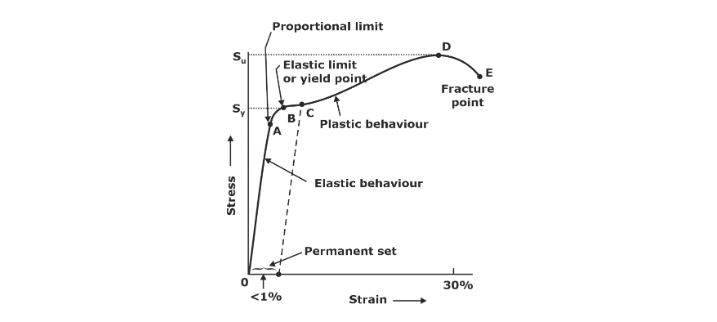

Stress-Strain Curve

When studying solids and their mechanical properties, information about their elastic qualities is crucial. This relation is important for the GATE ME exam. We can learn about the elastic characteristics of materials by analyzing the stress-strain relationships in these materials under varied loads.

The stress-strain curve of a material describes its stress-strain relationship. A stress-strain curve plots the stress and its related strain values. A stress-strain curve is illustrated below.

The stress-strain diagram’s various regions are as follows:

Proportional Limit

Hooke’s Law is obeyed in the region of the stress-strain curve. The stress-strain ratio offers us a proportionality constant known as Young’s modulus in this case. Point OA shows the proportional limit in the graph.

Elastic Limit

It is the point on the graph where the material returns to its original location once the load acting on it is eliminated completely. Beyond this limit, the material does not return to its previous position and begins to exhibit plastic deformation.

Yield Point

The yield point is where the material begins to deform plastically. Permanent plastic deformation happens after the yield point is passed. There are two yield points, upper and lower yield points.

Ultimate Stress Point

It is a point that represents the maximum amount of stress that a material can withstand before failing. Failure occurs after this stage.

Fracture or Breaking Point

It is the point in the stress-strain curve at which the material’s failure occurs.

Elastic Hysteresis

Elastic hysteresis is defined as the difference between the strain energy required to achieve certain stress in a material and the elastic energy of that material at that tension. During one testing cycle, this energy is wasted as internal friction (heat) in a material (loading and unloading).

Young’s Modulus of Elasticity “y”

The Mechanical property of a material to tolerate compression or elongation concerning its length is defined as Young’s modulus, also known as the modulus of elasticity. The elastic modulus of a material, such as Young’s modulus, bulk modulus, or shear modulus, measures the stress required to achieve a unit of strain; a larger modulus implies that the material is harder to deform. The pascal is the SI unit for this modulus (Pa). A material’s elastic limit or yield strength is the highest tension that can exist before the commencement of plastic deformation. The pascal (Pa) is also its SI unit.

![]()

Hooke’s law: Law of Elasticity

According to Hooke’s law, Stress and strain manifest themselves in very diverse ways in different contexts. Hooke’s Law states that stress and strain are normally proportional to each other for minor deformations. In most engineering applications, steel exhibits linear-elastic behaviour; Hooke’s law applies to it across its elastic range. Hooke’s law only applies to a portion of the elastic range in some other materials, such as aluminium.

Hooke’s Law Definition

Hooke’s law states that the strain of a substance is proportionate to the applied stress within its elastic limit.

When elastic materials are stretched or squeezed, the atoms and molecules disfigure until the force is released, and then they revert to their original state.

Hooke’s law Formula

Hooke’s law formula is represented mathematically within the proportional limit of material as follows-

σ = Eε

Where in SI units

- σ is the stress; Pa

- E is the modulus of elasticity or Young’s modulus, Pa (Normally GPa)

- ε is the strain, dimensionless

Elastic Materials Examples

Elasticity is the physical property of a material that permits it to revert to its original shape after being stretched or twisted by force. Elastic materials are seen in the following:

- Bungee Jumping.

- Elastic Waistband.

- Rubber Bands.

- Resistance Band.

- Spring Toys.

- Spring Mattress.

- Trampoline.

- Bow.

Get complete information about the GATE exam pattern, cut-off, and all those related things on the Byju Exam Prep official youtube channel.